By introducing a warehouse management system, Rullko Großeinkauf GmbH & Co. KG, a nationwide food supplier for communal catering and gastronomy, has created consistent transparency of stocks and processes. At the same time, order throughput times have been shortened, errors eliminated and food safety requirements further increased. proLogistik provided the necessary expertise, including software and hardware.

Our passion for quality” – under this maxim, Rullko has been supplying both commercial kitchens and restaurants throughout Germany with a wide range of food products for more than 90 years. Rullko employs around 150 people at its headquarters in Hamm, North Rhine-Westphalia, located directly on the A2 highway, where it stocks a full range of more than 20,000 items. Rullko Großeinkauf is certified in accordance with the IFS Logistics standard and is also a cooperation partner in the Intergast Großverbraucherservice Handelsgesellschaft mbH group of companies.

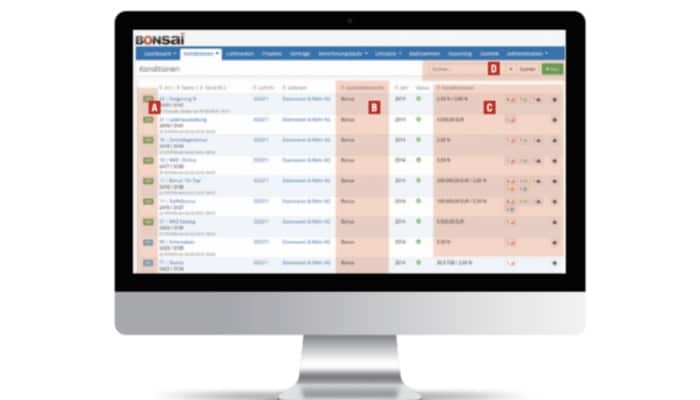

Improved performance at a glance

Fresh meat and sausage products, dairy products, dried goods, canned goods, drinks, frozen food and non-food items are stored on a total area of around 20,000 m². Accordingly, the areas are divided into dry, fresh, frozen and seasonal storage. Until the switch to end-to-end digitalized warehouse management, logistics were handled using pick lists that were processed manually.

“At the beginning of 2017, we decided to introduce a warehouse management system in order to increase stock accuracy, reduce errors in order picking and goods receipt and shorten order throughput times,” explains Uwe Langerbeins, Head of IT, Organization, Controlling, Logistics, Accounting and Administration at Rullko Großeinkauf GmbH & Co. At the same time, those responsible hoped to further improve traceability through optimized expiry date, RLZ and batch management.

Phase model creates security

The intralogistics system provider proLogistik, based in nearby Dortmund, was commissioned to implement the project: Uwe Langerbeins comments: “Short distances and the company’s many years of experience in the implementation of warehouse management systems were factors that influenced the choice of provider. No less relevant, however, was the fact that proLogistik not only supplies the software but also the necessary hardware from a single source.” The industry application pL-Store Foodline was also convincing. “With this solution, we offer a warehouse management system in which numerous functions that are particularly relevant for food wholesalers are already included as standard,” adds Richard Martin, who is responsible for Foodline industry sales at proLogistik.

After initial detailed clarifications in mid-June 2017, the specifications were approved just two months later so that implementation of the pL-Store Foodline warehouse management system, including its connection to the existing Microsoft Dynamics AX ERP system, could begin. Commissioning took place in four stages between February and July 2018. “The phase model was chosen to reduce complexity and therefore the implementation risk,” explains Richard Martin. For example, the Easter business is comparatively uncritical, so that customers would not be particularly affected by any teething problems that might arise. Consequently, the seasonal warehouse was equipped with the pL function modules Goods Receipt and Transports in order to start picking directly after the Easter goods had been received.

Paperless for increased productivity

The go-live was successively completed in the dry and fresh storage areas as well as in the deep-freeze warehouse set up at a separate location. Since then, order processing has been paperless throughout. Forklift trucks have also been equipped with on-board computers to handle transportation in the main warehouse and the deep-freeze warehouse. Furthermore, robust and handy data collection devices are used in the order picking area. Initial skepticism on the part of individuals towards the new technologies was quickly dispelled. “The phase model also proved its worth in this context, as the employees affected were able to be optimally prepared through on-the-job training in areas that had already been shut down,” says Richard Martin.

No complex adjustments required

Thanks to online inventory management, orders can be checked and processed in real time for plausibility with regard to the availability of goods. If Rullko also chooses this option in the future, partial quantities from different orders can be combined so that further routes can be saved. The statistics generated can be visualized and made available to other departments or used for presentation purposes.

Fit for current and future requirements

Rullko Großeinkauf in Hamm now manages a total of around 14,000 storage locations, spread across two warehouse sites, using the pL-Store warehouse management system. At the material flow level, constant adjustments to the daily order situation ensure the best possible coordination of available resources, such as means of transportation and personnel. “To say that there were no discussions or teething troubles during implementation would be dubious given the complexity of the project,” emphasizes Uwe Langerbeins.” But thanks to the implementation expertise of the proLogistik team and a partnership of equals, any nascent problems were always quickly resolved.”

With further improved, system-supported traceability of goods, food safety is also guaranteed in the future.