pLG Warehouse Management System

OVERCOMING CHALLENGESVolatile markets, rising cost pressure, fluctuating demand patterns, and increasingly smaller order volumes – combined with the demand for ever shorter delivery times, maximum delivery quality, and efficient returns management – place high demands on a powerful warehouse management system.

To meet these challenges, companies need a WMS that ensures transparency, intelligently controls processes, and adapts flexibly as requirements grow. Only then can efficiency, speed, and quality be consistently maintained. Whether you are implementing a WMS for the first time or modernizing existing systems, proLogistik supports companies of all sizes with customized software solutions.

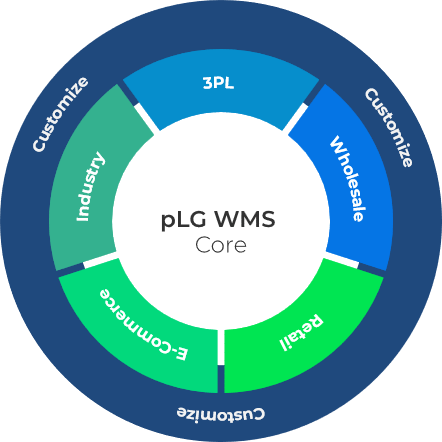

Modulares Warehouse Management System

Customization to Meet Your NeedsThe pLG Warehouse Management System combines a powerful core with seamless integration into enterprise resource planning (ERP) systems such as SAP, Infor, or Microsoft Dynamics – supported by proven standard interfaces.

With industry-specific configurations for 3PL, manufacturing, e-commerce, wholesale, and retail, as well as comprehensive customization options, we rank among the leading providers on the market. Our mission: to deliver a future-proof solution that stays at the cutting edge of technology through continuous development.

In addition, we offer a high-performance Transport Management System (TMS) and robust hardware solutions that are perfectly aligned with our WMS – all from a single source.

This creates an integrated process landscape, from the loading dock to the last mile.

Discover the many advantages of the pLG WMS

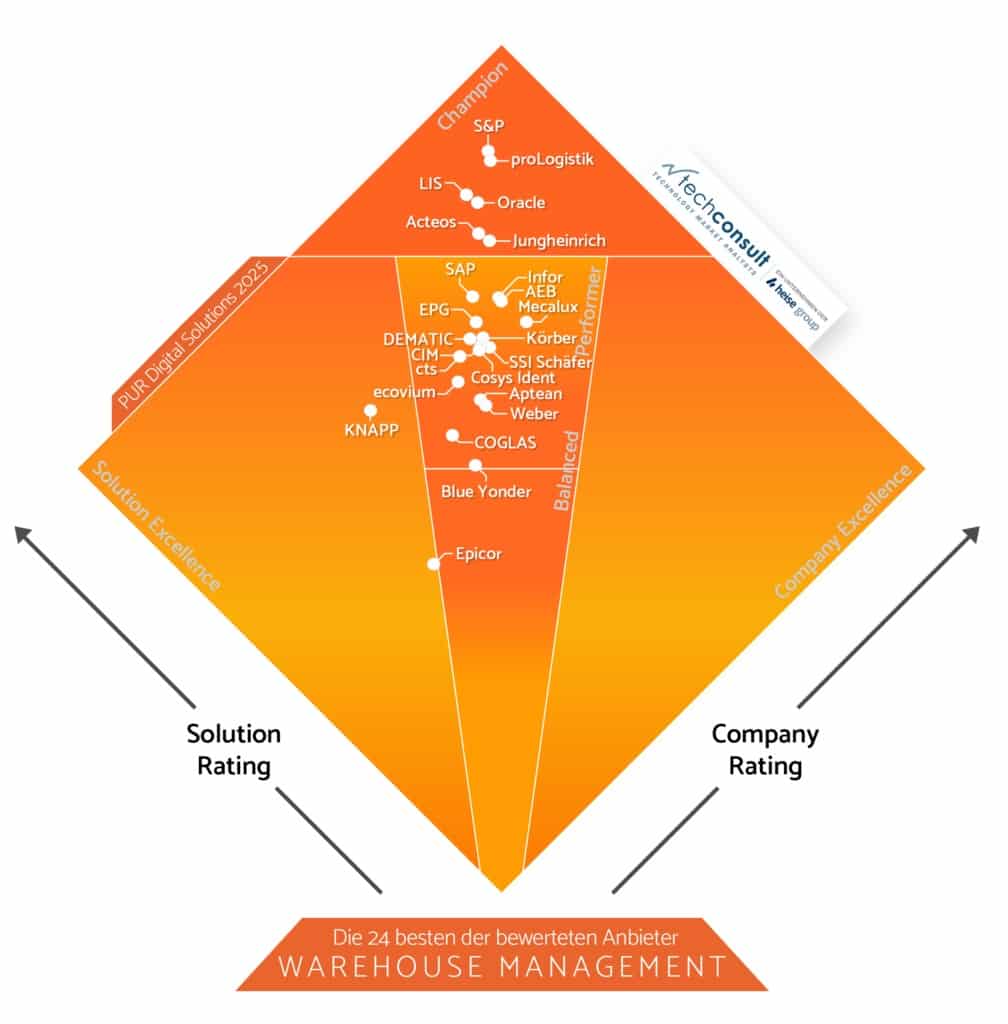

Advantages in figuresTop Rated: pLG WMS in the Professional User Rating 2025

Playing in the Champions LeagueThe pLG WMS has been recognized as a Champion in the Professional User Rating: Digital Solutions 2025 in the category Warehouse Solutions.

This award reflects our outstanding performance in two key areas:

our strong market focus and the exceptional quality of our digital solution.

As one of the leading providers in the German-speaking market, we greatly value the direct feedback from our users – a true testament to trust, innovation, and customer proximity.

We sincerely thank our customers for this great recognition.

Testimonials

WHAT OUR CUSTOMERS SAYRevolutionizing Production Processes at Otto Christ AG

success storyHere you can find the Success Story and get an insight into the project with our customer.

pLG WMS – additional functions

Always up to dateAt the proLogistik Group, we aim to continuously develop our WMS in order to integrate the latest technological innovations and respond precisely to the individual requirements of our customers.

- Empties and loading aids

- (Multi-)client capability

- Multiple storage capability

- Forklift guidance system

- Value Added Services

- Billing module

- Consignment

- Batches & minimum shelf life

- Autostore & lift cabinet module

- Double/multiple depth storage

- Dangerous goods/Hazardous materials

- Weight control

- Cross Docking

- Package optimization

- Production supply

- Resource planning

- Returns management

- Serial numbers

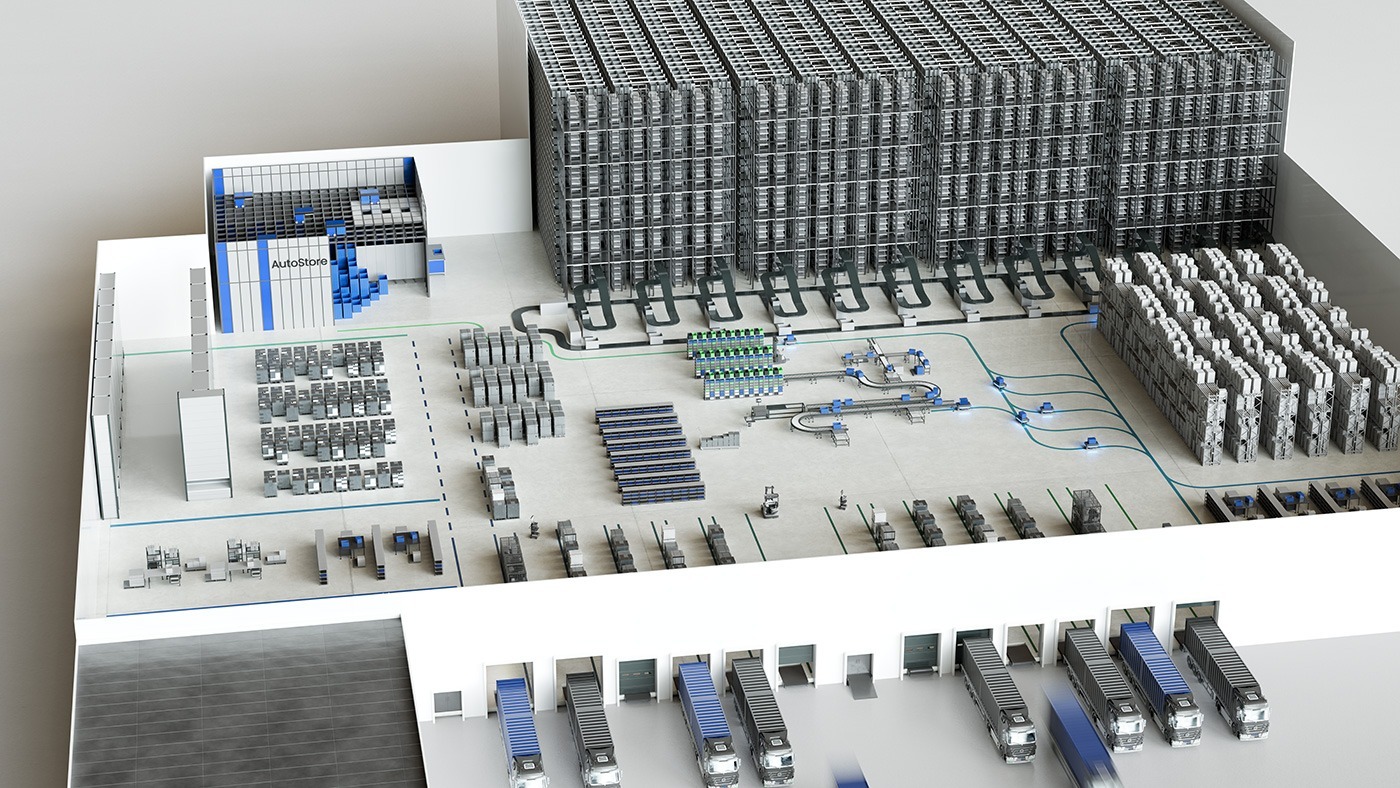

Warehouse Management System

Successfully in use with well over a thousand installationsThe image illustrates a modern, fully digitalized warehouse environment – from goods receipt to automated storage solutions such as AutoStore and high-bay warehouses, through to order picking, packaging, and shipping at the dock. All process steps are interconnected, optimized, and part of an integrated supply chain – powered by proLogistik’s high-performance software solutions. The result: maximum transparency, efficiency, and real-time control.

- Order-oriented picking

- Multi-stage picking

- Multiorder picking

- Parallel picking

- Freestyle picking

- Picking ready for dispatch

- Store-specific order picking

- Goods-to-person picking

- Pick-to-Light

- Put-to-Light

- MHD-controlled picking

- Work & packing stations

- Labeling

- Logistic manufacturing

- Assembly, packaging & display construction

- Quality control

- Order picking

- Returns management

Free Whitepapers & Brochures for Download

Wholesale – one of the most versatile requirement profiles for warehouse management systems.

Strong warehouse management systems in the retail sector

You may also be interested in:

Digital inventory management – directly from the cloud.

Keep returns under control – fast, digital, and fully traceable.

We will be happy to advise you on our products

We are here for you.Give us a call or send us a message. We look forward to welcoming you.

proLogistik Holding GmbH

Fallgatter 1

44369 Dortmund

Tel.: +49 (0) 231 5194-0

Tel.: +41 (0) 44 200 40-00

Tél.: +33 (0) 251 81 85 85