Equip yourself with a warehouse management system for

the future of your industry

PLG WMS LOGIS MOVE – The Warehouse Management System for Industry & ManufacturingThe WMS LOGIS MOVE is a modular and easy-to-use

Warehouse Management System (WMS). It guarantees maximum efficiency and safety

for your production logistics.

To secure the production supply, the

WMS LOGIS MOVE via a special production module.

The software was developed and programmed entirely by proLogistik Schweiz AG (formerly Dataphone AG) in Switzerland. LOGIS MOVE is also 100% release-capable.

Webinar recording

We offer you the recording of the WMS webinar with the focus “Production module of the WMS software LOGIS MOVE” free of charge. This webinar recording provides you with compact and informative information about the Warehouse Management System in production logistics.

Have we aroused your interest? Then get in touch with us without obligation.

Structure of the Warehouse Management System

“The right stock in the right quantity in the right place at the right time!”A three-stage software structure is the basis for the success of WMS LOGIS MOVE. A stable core as the basis, the powerful product standard as the main layer and the option of a small customer layer if customer-specific functional enhancements are required.

The product standard is constantly being further developed, optimized and in some cases supplemented by changes requested by our customers. The aim is always to keep the customer base as small as possible. This facilitates version updates and automatically extends the life cycle of LOGIS MOVE.

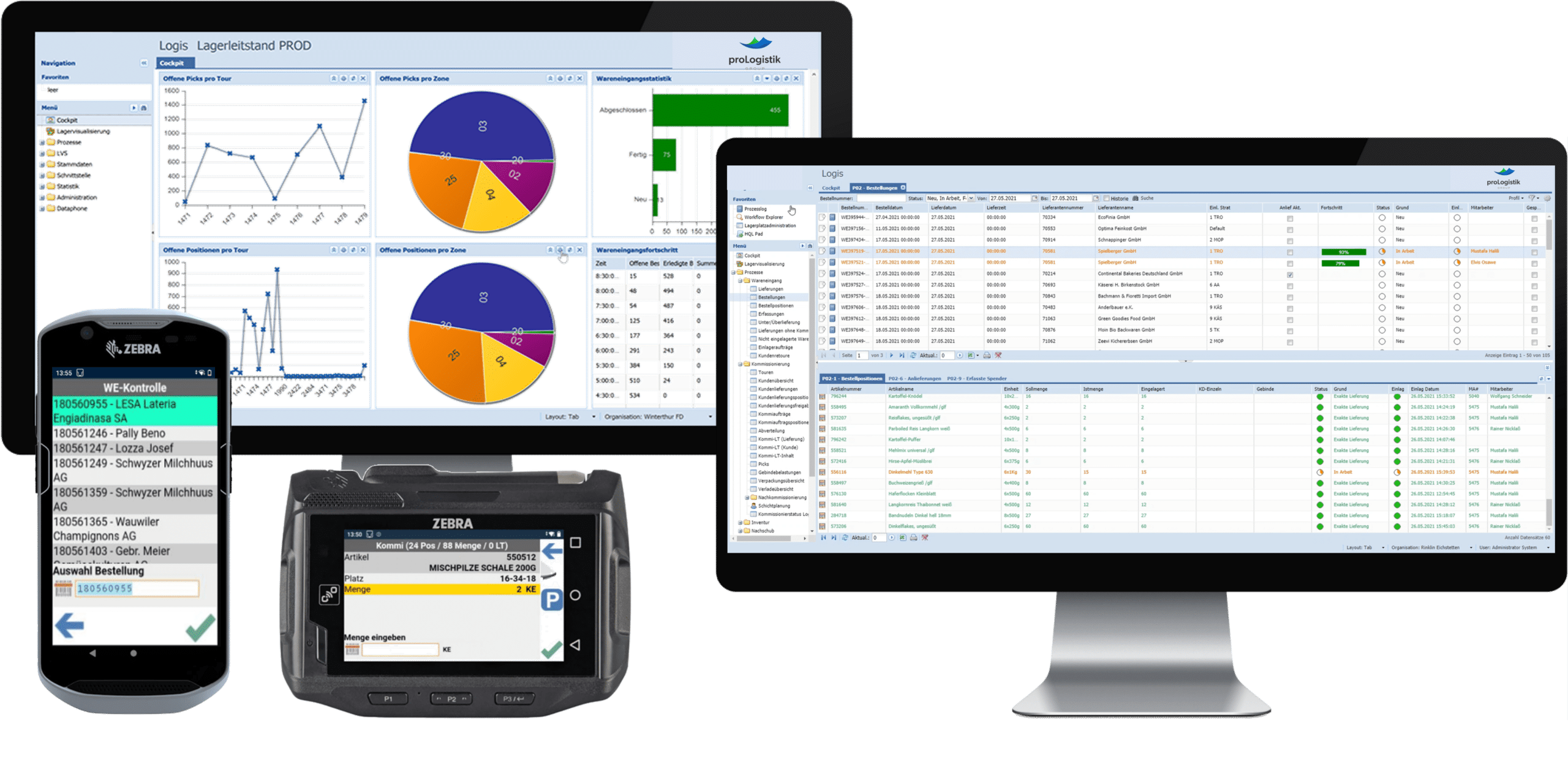

View in the control center

All processes can be controlled and monitored and configurations can be made via the LOGIS MOVE WMS control station: Store or adapt strategies, analyze and rectify errors and intervene in ongoing operations.

Order processing is always displayed transparently throughout the day, and the percentage of work progress per storage area can be displayed continuously. This makes it possible to see at any time in which storage areas work progress is slower or faster. Employees from the faster areas can be assigned to the slower areas via the console, and this balanced load distribution ensures that they finish work as early as possible.

View on the mobile client

The client application is a web application that can be configured for different types of terminal devices and can therefore be operated by MDE devices, forklift terminals or stationary workstations alike.

KPIs via the cockpit

Data for warehouse optimization can be obtained by evaluating the movement data: Item turnover, performance per storage area, employee performance, etc. These key figures are used to optimize and increase efficiency. For example, B-items with a high turnover can be reclassified as A-items and given a more attractive picking location. Employee performance is used for personnel deployment planning, particularly in the event of strong seasonal fluctuations.

Interface to peripheral systems

Dataphone works with a specially developed Business Connector Suite to connect LOGIS MOVE to ERP systems or automation solutions. This enables LOGIS MOVE to be connected to peripheral systems via the relevant market technologies.

WMS LOGIS MOVE function overview

A warehouse management system must be able to manage the entire intralogistics process error-free and paperless. This requires precisely coordinated processes, as this is the only way to control stock levels, process orders quickly and ensure reliable workflows.

Why a modern warehouse management system is necessary:

- Reduce costs

Reduce costs thanks to forward-looking warehouse planning, fewer stock-outs and better warehouse utilization. - Avoid mistakes

Guided picking avoids errors. - Increase efficiency

Automated processes and mandatory documentation increase the efficiency of your warehouse.

- Save time

The WMS always chooses the shortest route and continuously optimizes the processes. This saves you time and allows you to adapt your resource planning. - Green Logistics

By using modern warehouse management software, warehouse logistics processes can be made significantly more environmentally friendly and resource-efficient.

Flexible, efficient and future-proof warehouse management

Finely tuned processes and professional equipment are required to ensure that the right quantity and quality of products are in the right place at the right time.

Dataphone AG, based in Switzerland and a member of the proLogistik Group since June 2021, has built up extensive expertise over decades of service provision, which it can draw on when implementing and optimizing your warehouse management.

Smooth processes in intralogistics

At the same time, the system landscape of the warehouse management software is being continuously developed in order to be able to react flexibly and efficiently to new market requirements.

We are the experts for the successful introduction, replacement and further development of your intralogistics. To be able to offer you the perfect solution, we need information about your requirements. Let us know what you are looking for and we will develop your personal warehouse management software.

The proLogistik Group offers the possibility to digitize your supply chain step by step, depending on the situation.

Do you know the 9 advantages of digital warehouse management?

- Cost reduction through fewer stock-outs

-

Time savings thanks to optimized warehouse processes

-

Increased inventory security with better planning options

-

Reduced excess stock of individual items

-

Increased efficiency through forward-looking warehouse planning

-

Increased productivity through paperless picking

-

More transparency about warehouse operations

-

Quality assurance through complete documentation

-

Optimum personnel planning through better warehouse utilization

You can find out everything you need to know about the LOGIS MOVE WMS software solution for production exclusively in the webinar recording;

proLogistik Schweiz AG

May we also advise your company on optimizing your intralogistics?Formerly Dataphone AG

Schaffhauserstrasse 611

CH-8052 Zurich

info@dataphone.ch

+41 44 200 40 00

Dataphone AG has been part of the proLogistik Group since June 2021 and will be renamed proLogistik Schweiz AG as of 01.01.2024.

Questions, requests or suggestions?

We are here for you.Give us a call or write us a message. We look forward to seeing you.