HONSEL Umformtechnik GmbH has built a new production facility, including a connected logistics section, at the company’s central headquarters in Fröndenberg an der Ruhr.

Sector: Industry

About HONSEL Umformtechnik GmbH

- Founded in 1930

- Headquarters in Fröndenberg an der Ruhr

- 300 employees

- Automotive industry as the largest customer

- 2,500 square meters of floor space

- 1,300 parking spaces

Products made of wire – with the highest precision. This is a brief outline of the demands that HONSEL places on its own products. The portfolio ranges from simple cold-formed parts, such as rivets, nuts and bolts, to specially finished custom-made products and process-monitored systems for rivet automation.

New building as an opportunity to restructure finished goods logistics

In view of the constant growth in demand, HONSEL is constantly investing in capacity expansions at an operational level. A new production area with a direct conveyor connection has been created on 2,500 square meters of floor space. “We decided to introduce the goods-to-person process at intralogistics level in order to relieve our staff of long walking distances and search processes, while at the same time being able to operate more efficiently,” says Thomas Kleinert, Head of Operational Logistics. At the same time, the aim of the new system solution was to further increase the level of service for customers and overall quality. “As part of our digitalization strategy, it was also important to implement warehouse management software that communicates with the ERP system without media discontinuity and enables paperless, mobile working,” continues Thomas Kleinert.

Advantages of the proLogistik Group software

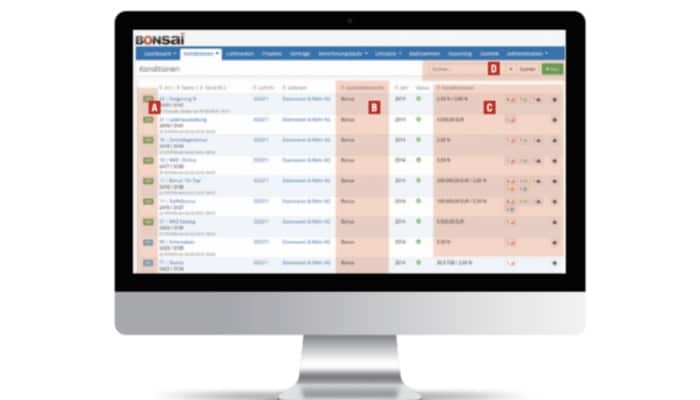

The synchronized communication and interaction between the ERP and warehouse management system (WMS) ensures inventory and process reliability in daily operations. At the same time, by implementing the goods-to-person principle, it was possible to achieve a high picking performance with a reduced workload.

Quality standards also met in logistics

The smooth interaction of mechanics and software in the area of intralogistics ensures that requested goods are provided promptly and efficiently in line with demand. The pL-Store® WMS from the proLogistik Group, which went live within a few months of the kick-off meeting, creates end-to-end transparency and provides an (online) overview of the entire material flow.

“The quality of logistics has been significantly improved. This has a direct impact on the level of service, which we are continuously improving in the interests of our customers.”

Thomas Kleinert, Head of Operational Logistics