At Hammer’s new logistics campus in Eschweiler, the multi-client-capable warehouse management system pL-Store® ensures fast, error-free and efficient omnichannel fulfillment. The 3PL provider has thus created the prerequisites for fully supporting its customers’ cross-channel supply concepts and also being able to flexibly meet new requirements. At the same time, the course was set to further strengthen the market position gained in a challenging environment.

Hammer GmbH & Co KG, headquartered in Aachen, is one of the largest logistics service providers in the region. Together with the Hammer Group and other partners, the family business, which has been owner-managed for more than 70 years, operates a global service network in over 25 countries.

Capacity increase to more than 105,000 square meters

For many companies, outsourcing is still a sensible alternative to in-house logistics in terms of quality and cost-effectiveness. “We want to continue to grow and have invested in the construction of the Logistics Campus Eschweiler – LCE for short,” reports Tim Wilhelm Hammer, Head of Logistics.

Focus on peak-compliant pick performance

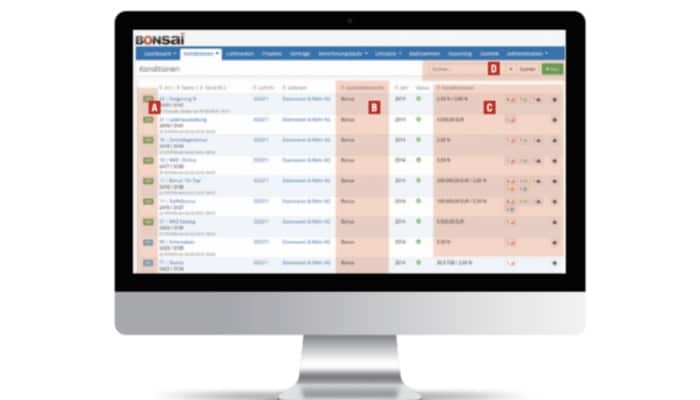

This is not the first time Hammer has relied on the high-performance Warehouse Management System (WMS) pL-Store® from proLogistik for warehouse management and material flow control. The collaboration with the Dortmund-based intralogistics system house began in 2008 with the introduction of the standard software in Pullheim. From the fourth quarter of 2021, special processes were installed to handle the B2C order volume generated online during the onset of the peak season. The focus of the design was on speed and zero-error tolerance in the picking area.

Incoming goods as an enabler for clearly structured processes

Since the commissioning of the LCE, the pL-Store® WMS has laid the foundation for consistent control of the subsequent material flows with unique labeling based on a load carrier ID number at goods receipt. Taking into account the dimensions, weight and ABC classification, the software then automatically defines the ideal storage location allocation based on plausibility criteria, so that the storage space and capacities are used in the best possible way.

Automatic fill quantity calculation and replenishment

Goods are measured, weighed and recorded in WMS proLogistik in the goods receiving area of the automated small parts warehouse, where 30 shuttles operate on 20 levels. Intelligent warehouse pre-planning also automatically organizes replenishment requests, taking into account all active orders, so that even small parts warehouse capacities are used optimally. Also mapped in the WMS are the weight control and error ramp, connected modules such as elevators, continuous conveyors, conveyor technology loops, five goods picking stations, a sorter for collective collection and 13 packing stations connected by container and carton conveyor technology…

Intelligent strategies for a constant flow of materials and work

Once the order has been received, pL-Store begins transporting goods from minivans to the picking stations via automated shuttles. The calculation is based on the collective order principle for all incoming orders. It is also possible to pick directly into shipping cartons, whereby filling quantity calculations also apply here, so that perfectly coordinated packaging is always available.

Optional direct retrieval and separation in goods issue

In order to process large quantities of individual orders from the B2C business efficiently and in a time-saving manner, the classic picking and packing process can be skipped if necessary. The goods are reserved directly via an interface from an online store system when the order is released. pL-Store generates the corresponding transport orders and uploads them to the mobile data collection devices. In this case, too, the registration with the CEP service provider and the generation of the shipping label incl. Tracking number automated. This means that these units can also be sent to retailers or end customers as quickly as possible.

Powerful and flexible for the future too

“With the new logistics campus in Eschweiler and end-to-end digitalized processes, we are now in a position to implement our clients’ multi-channel concepts in the best possible way. This also means that we can look forward to peaks such as Black Friday or Cyber Weeks with confidence,” summarizes Tim Wilhelm Hammer. As the term implies, the continuous improvement process is of course not yet complete. The simulation tool pL-Sim included in pL-Store can help to emulate, evaluate and further develop corresponding AI solution approaches.