HONSEL Umformtechnik GmbH has built a new production facility, including a connected logistics section, at the company’s central headquarters in Fröndenberg an der Ruhr. This is where the finished products are temporarily stored and prepared for dispatch on an order-related basis. The synchronized communication and interaction between the ERP and warehouse management software (WMS) ensures inventory and process reliability in daily operations. At the same time, by implementing the goods-to-person principle, it was possible to achieve a high picking performance with a reduced workload.

Products made of wire – with the highest precision. This is achieved by cold forming, a production process that the traditional Fröndenberg-based company has continuously refined over its more than 90-year history. The HONSEL Group currently has around 300 employees worldwide. They are all united by the goal of maintaining the defined quality standards at the highest level. New building as an opportunity to restructure finished goods logistics.

In view of the constant growth in demand, HONSEL is constantly investing in capacity expansions at an operational level. The latest coup is the so-called “Plant 3”, which was built at the headquarters in Fröndenberg/Ruhr and went into operation at the beginning of 2019. “We decided to introduce the goods-to-person process at intralogistics level in order to relieve our staff of long walking distances and search processes, while at the same time being able to operate more efficiently,” says Thomas Kleinert, Head of Operational Logistics. standard software with individual applications.

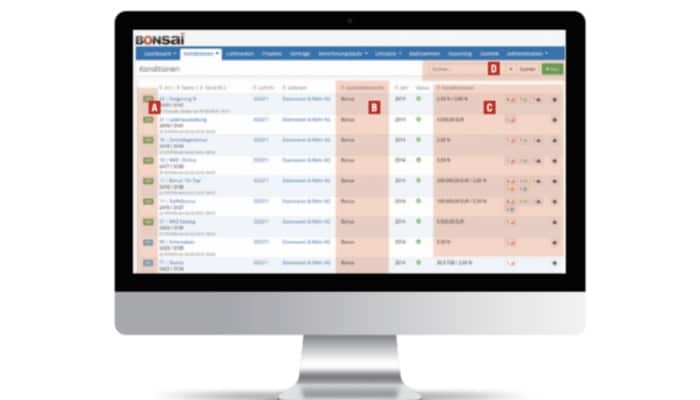

The choice fell on pL-Store from proLogistik, a standardized warehouse management system with integrated material flow control. The project started at the end of June 2018 with an on-site kick-off in Fröndenberg. On the one hand, this concerned the conveyor technology connection for the realization of the goods-to-person approach, but also the goods receipt from production, including the optoelectronic 100% quality control that is standard at HONSEL.

The pL-Store warehouse management system already has a standardized integration component, via which it has been linked to the higher-level ERP system of the partner proALPHA that is currently in use. With “iGo pilot navigation”, the device also has an assistance system that guarantees driving safety even at high speeds and is used for navigation in the warehouse.

Only plastic pallets are used as load carriers, which are equipped with both containers and cartons. They are fed in from production via a storage infeed and placed on the storage/retrieval infeed via the conveyor system with the help of the transverse transfer car. The warehouse management software transmits a transport order, the narrow-aisle stacker picks up the pallet and stores it according to the instructions. Around 1,300 storage locations managed by the warehouse management system have been set up in the two aisles.

The retrieval process is similar. Goods requested for order-related picking are provided pallet by pallet by the cross transfer carriage at one of the two picking stations. The picking area comprises six pallet spaces, three of which are to be processed by one worker. The orders are transferred to the handset. He then assembles the requested small load carriers. Only full KLTs are removed from the pallet; they are not opened.

To ensure that the correct article is always picked, the KLT label is counter-scanned. The article number and batch are checked. After each pick, the quantity is reported back to proALPHA and the ERP system generates the corresponding shipping labels. After picking, the employee receives the message “Pallet is being removed”. If there are still goods on the pallet, the transverse transfer carriage takes over again and transports them to the storage infeed in the pre-zone of the narrow-aisle warehouse. Empty load carriers are removed from the picking line.

Solid hardware for specific requirements

The WE hand trolley is also characterized by swivel castors, a parking brake, an integrated cable duct and storage areas. The battery box has the advantage that the handcart can be used independently of the power supply.

Quality standards also met in logistics

One of the guiding principles of HONSEL Umformtechnik GmbH is: “We work for our customers – optimum technical development support, maximum productivity and punctual deliveries are our top priority.” With the new Plant 3, the company is once again underpinning this maxim. The warehouse management system from proLogistik, which went live within a few months of the kick-off meeting, creates end-to-end transparency and provides an overview of the entire material flow.

“The quality of logistics has been significantly improved. This has a direct impact on the level of service, which we are continuously improving in the interests of our customers.” Further advantages are provided by the software-supported permanent inventory, which enables stock levels to be recorded and updated without time restrictions during ongoing operations.