The ongoing dynamic of change is also challenging intralogistics. Flexible, agile and efficient processes are a “must-have” in order to meet these challenges in the long term. However, making costly investments is sometimes not an option. Alternatively, a retrofit can achieve great things. Warehouse Management Systems (WMS) play a decisive role here.

Change has always been a constant. However, the pace has picked up in light of the pandemic and the change in demand behavior. It has also become apparent that systems and processes that have proven themselves over a long period of time are reaching their limits and are showing signs of chronic exhaustion in a figurative sense. Developments in online retail are also contributing to this. While e-commerce has been established as the “new normal” in the B2C sector for years, but has received a further boost due to coronavirus, this sales channel is also increasingly shaping B2B business. Intralogistics must also meet the associated requirements. However, if this is only partially successful, it is not necessarily a question of the existing system or the existing storage system. Rather, the required target status in terms of performance can be achieved with comparatively little effort through a retrofit at the warehouse management and control level, parallel to the reorganization of the processes.

Tapping into performance potential across the board with a retrofit

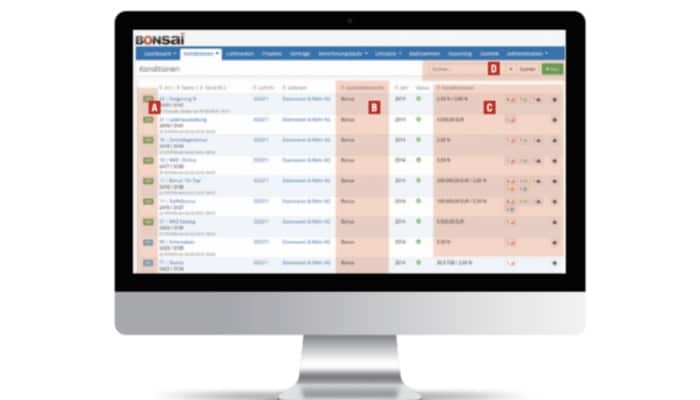

The unrelenting cost pressure is also forcing companies to optimize their process and cost structures in the field of intralogistics. At the same time, the customer is increasingly setting the pace and expects high delivery quality with short delivery times in addition to availability and permanent information capability. This is precisely where modern warehouse management systems, such as the pL-Store® WMS, come in, offering a wide range of opportunities for improved process organization based on extensive functionalities for warehouse management and control. It also allows the integration of new business models tailored to customer requirements. The system enables you to log all transactions and bookings online. Visualization creates transparency throughout, fewer errors occur and search times are eliminated or noticeably reduced. With the help of calculations, processes can be continuously optimized and storage space perfectly utilized. In this context, pL-SIM, a simulation tool that allows you to run through, compare and evaluate possible processes, is particularly helpful. This makes it possible to gain an initial impression of how planned processes or material flow movements might look and the extent to which they fit seamlessly into the overall process. This allows you to organize your warehouse more efficiently and more economically and to react flexibly to changes at any time and map them at an operational level. Well-founded key performance indicators (KPIs) also assist in making accurate decisions.

Staying competitive and securing future viability

All in all, a retrofit based on a high-performance, standardized WMS creates the conditions for optimal and efficient utilization of all resources, ensuring high availability combined with short throughput times and excellent delivery quality. At the same time, you increase your ability to provide information and keep your promises. This is also immensely important, especially in e-commerce, in order to retain customers in the long term. But even the employees benefit: Processes are simplified, tedious searching is eliminated and operation is extremely simple as it is intuitive. This idea of simplification is also part of the concept of “Industry 4.0” or “Logistics 4.0”, a goal that companies are coming a step closer to in the course of the retrofit, also thanks to digitalization. Such a transformation based on adapted, modernized and sustainable intralogistics ultimately prepares the ground for increased competitiveness, growth opportunities and future security in dynamic markets.

Know-how transfer and cost-efficient implementation

proLogistik supports you on this path – with more than 35 years of expert knowledge in the field of intralogistics process modernization. Our offer for your retrofit project:

- Free inventory of the current situation

- Consultation with initial rough concept

- Detailed offer

- Creation of specifications

- Joint planning of the changeover scenario

- Training employees on the new pL-Store® WMS

- Commissioning (in one or more steps)

- Support during the ramp-up phase

- After-sales service = long-term guaranteed support