To ensure that customers of P.W. Hieronimi moderner baubedarf GmbH can continue to rely on their building experience in the future, the Faid/Cochem-based building materials retailer has introduced the WMS pL-Store® Techline.

Industry: Building materials wholesale

About Hieronimi

After celebrating its 125th anniversary in 2015, Hieronimi, a medium-sized company with more than 200 employees at seven locations, is now the largest building materials retailer between Koblenz and Trier. It is also a co-founder of the Allianz “Bauspargruppe”, which currently has a total of 47 branches throughout Germany.

Highlights

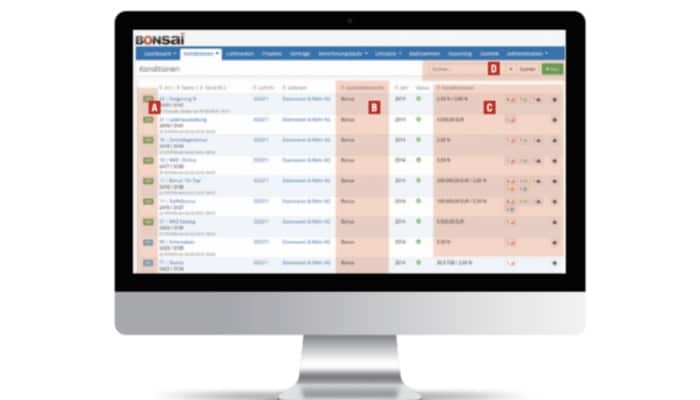

The standard software pL-Store® Techline supports all processes from goods receipt to batch management, online inventory management, chaotic and fixed storage location management, barcode control, paperless picking and freestyle picking for counter handling through to goods issue. At Hieronimi’s request, additional applications that are specifically relevant to the company have also been added. For example, it should be possible to record the license plate number for immediate or self-collectors.

Everything from a single source – software + hardware

A monitor was also installed to show customers their current order processing status in the waiting area. It also had to be ensured that loading aids used in goods issue were reported back to the ERP system for calculation purposes. Also shown are a paint mixing plant, as mixed paint is not a stock item, and a concrete mixing plant, which required a separate replenishment process for bulk material.

Other branches follow

Following the introduction of the new WMS solution in Mülheim and, since December 2018, also in Wittlich, employees have been using both mobile data collection devices and industrial PCs (IPCs). The Daun branch followed as the third location in July 2019. One of these IPCs is used on a trolley in the incoming goods area. Another, somewhat smaller 10.4-inch device is carried as an on-board computer on a forklift truck. Typical features of these compact “assistants” are a wear-free, capacitive touch surface and a plastic housing that is resistant to aggressive influences and (impact) shocks. Special laminated safety glass increases the service life of the appliances many times over.

“We chose pL-Store® Techline because it is an application that specifically covers the needs of the building materials industry. “Julia Falkenburg, Project Manager at Hieronimi