As part of a pilot project, Fassbender-Tenten initially introduced the standard software pL-Store® Techline from proLogistik at three locations. Shorter order throughput times and an overall improvement in delivery quality quickly followed. In view of these results, the warehouse management and control solution, which is tailored to the specific requirements of the industry, is now to be rolled out gradually to other branches.

The company, which is also a partner of the “Bauspargruppe” cooperative, also offers services such as container services, the rental of machinery and equipment, installation support, construction waste disposal as well as training and consulting.

More efficient processes on the agenda

The product range of the building materials retailer headquartered in Bonn comprises around 59,000 parts, 8,719 of which are actively stocked. Stocking takes place both in the specialist store itself and in adjacent warehouses. There are also pallet and cantilever racks as well as block and bulk storage areas in the outdoor area. Until the new warehouse management software pL-Store Techline from proLogistik went live, order picking was organized conventionally and manually. “Document-based order processing not only involved a great deal of effort, but also proved to be increasingly error-prone and in need of repeated correction in view of the constantly growing range of products,” reports Hans Peter Ostermann, Project Manager at Fassbender-Tenten. The proportion of immediate or self-collection customers, for whom comparatively short lead times are of primary relevance, has also increased significantly.

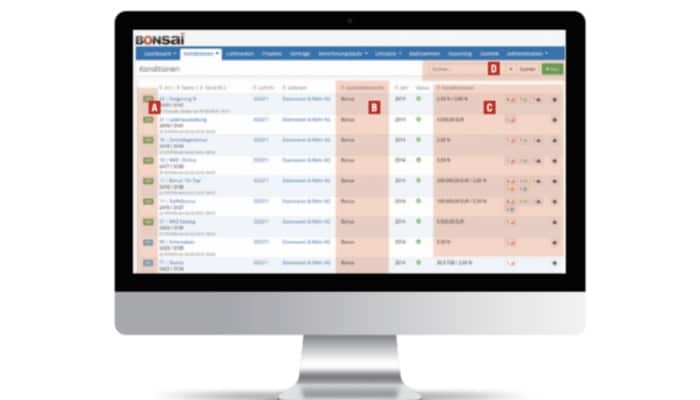

After setting up the gevis ERP system from the strategic proLogistik partner, Münster-based GWS Gesellschaft für Warenwirtschafts-Systeme, five years ago, the retail company has now taken another important step towards digitalization. In the course of this, a standardized software solution for warehouse management and control was developed on the basis of the pL-Store-LVS together with Hieronimi GmbH from Faid/Cochem, which also operates within the “Bauspargruppe” – also taking into account the continuation of a common reporting standard. This application has been used by both partners since the beginning of 2018 and is gradually being rolled out to all branches.

Hardware and software from a single source

This is accompanied by the objective of creating transparency throughout, so that an overview of current stocks and goods movements is ensured at all times. “Last but not least, we want calculable costs for the maintenance and servicing of the system and are relying on the advantages of permanent inventory,” continues Hans Peter Ostermann. Alongside the software, the intralogistics system house from the Westphalian metropolis of Dortmund supplied the required number of handheld devices for mobile data collection as well as powerful, compact industrial PCs. The 12.1-inch IPCs are used on trolleys in the incoming goods area.

Industry-LVS adapted to individual requirements

The project started in March 2017 with proLogistik drawing up the specifications. The first go-live of the new warehouse management solution took place in February 2018 at the Fassbender-Tenten site in Rheinbach. Now that the company had gained initial experience with the new software application, including paperless picking, it went live in Cologne-Zollstock in February 2019 and in Cologne-Bickendorf in May. “The data quality has already been significantly improved,” says Aram Skripin, who has been responsible for the introduction of pL-Store Techline at Fassbender-Tenten as Head of Sales Processes and Logistics since April 1, 2019. His many years of experience in the building materials trade with this warehouse management system should help to make commissioning even more efficient and faster in the other branches. For example, a customer monitor was installed in the waiting area to show each individual the processing status of their order. It also had to be ensured that loading aids used in goods issue were reported back to the ERP for invoicing.

Special consideration was also given to cash sales as early as the goods issue process. It is important here that the order picker is shown the invoice already presented to the customer at the beginning so that he knows whether or not loading aids have been sold at the same time. This enables real-time identification and ensures traceability for the customer. In addition, batches can be tracked seamlessly along the entire process chain.

The switch from paper-based picking to digitalized processes, including mobile data capture, naturally also placed new demands on operational staff. This further simplifies the coupling of the systems. Another advantage of smooth interaction is the increased ability of employees with customer contact to provide information.