Implementation of the warehouse management system pL-Store® Foodline including the use of proLogistik hardware.

Industry: Food wholesale

About Rullko Großeinkauf GmbH & Co KG

- Headquarters in Hamm

- 150 employees

- 20,000 square meters of storage space

- 20,000 articles

- 8,000 customers

- Vehicle fleet with approx. 25 tours per day

Initial situation

“At the beginning of 2017, we decided to introduce a warehouse management system in order to increase stock accuracy, reduce errors in order picking and goods receipt and shorten order throughput times,” explains Uwe Langerbeins, Head of IT, Organization, Controlling, Logistics, Accounting and Administration at Rullko Großeinkauf GmbH & Co. At the same time, those responsible hoped to further improve traceability by optimizing best-before and expiration date and batch management (best-before date / expiry date = remaining shelf life).

Advantages of the proLogistik Group software

Since commissioning the pL-Store warehouse management system, the food wholesaler has benefited not only from paperless picking but also from a wide range of industry-specific functions within the warehouse management system. These include:

- Online inventory management

- MHD processing from goods receipt with remaining shelf life

- Temperature detection

- Organic goods handling

- Space management with integrated optimization processes

- Applications for customized awards

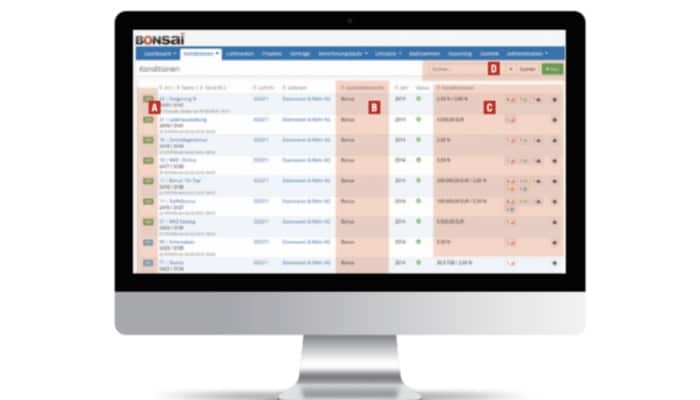

Rullko also uses a reporting tool implemented by proLogistik. The aim here is to identify further potential for improvement through systematic monitoring in order to continuously improve performance in all storage zones.

Fit for current and future requirements

Rullko Großeinkauf in Hamm now manages a total of around 14,000 parking spaces, spread across two warehouse locations, using the pL-Store-LVS. At the material flow level, constant adjustments to the daily order situation ensure the best possible coordination of available resources, such as means of transportation and personnel. The interaction between software and hardware also speeds up processes and minimizes errors, whether in incoming goods or during order picking.

With further improved, system-supported traceability of goods, food safety is also guaranteed in the future.

“The industry application pL-Store® Foodline was also convincing – “With this solution, we offer a warehouse management system in which numerous functions that are particularly relevant for food wholesalers are already included as standard.”

Richard Martin, Foodline sector sales at the proLogistik Group