With the successive implementation of a new ERP system and industry-specific warehouse management software, Nowebau has put its business processes in Großefehn on a new, powerful and solid footing.

Industry: Building materials wholesale

About Zentrallager Nowebau GmbH & Co. KG

- Company headquarters in Großefehn

- 87 locations

- 2,000 employees in the Nowebau Group

- 80,000 m² area

- 10,000 pallet spaces

- Delivers to 100+ customers 2x per week

- approx. 80,000 tons of goods shipped per year

Initial situation

Until September 2017, intralogistics was controlled solely via the ERP software, which also includes a module for inventory management. “The disadvantage, however, was that printed route and pick lists were in circulation and special knowledge of the stocks and their storage locations was required,” reports Marco Emken, Managing Director of the Nowebau central warehouse. “This was exacerbated by the immense time pressure, which untrained employees in particular were barely able to cope with.” The question of whether the availability signaled by the ERP system was actually given in reality would also often have arisen in the context of customer support.

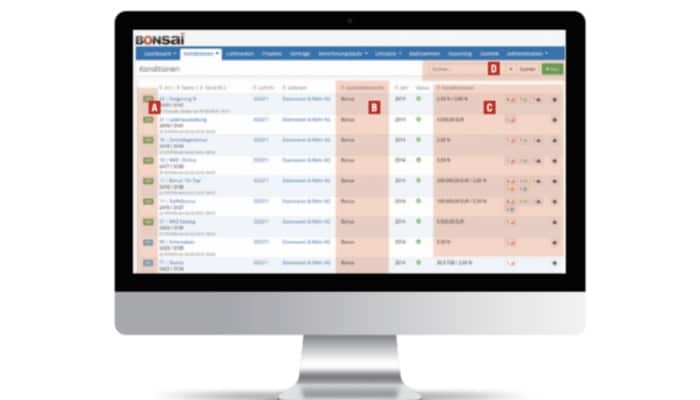

(LVS) pL-Store® Techline with pre-programmed interface in ERP

This software solution for warehouse and material flow control was specially designed for the building materials and sanitary industry as well as technical wholesalers and already covers their special requirements profile as standard.

Since the go-live, all intralogistics processes have been controlled exclusively via pL-Store® Techline. The software communicates with the ERP system, via which incoming orders are recorded and transmitted to the WMS.

Thanks to the immediate transmission of each individual order, those responsible can prepare the picking and collect the required goods at a special storage location within the halls.

Making good things even better and future-proof

Another decisive advantage of pL-Store® Techline for the building materials trading company is the multi-client capability of the warehouse management system. With a significantly increased depth of information, individual business processes, which can be flexibly modeled, as well as the respective order status are clearly differentiated. It was also important that processes did not have to be completely redesigned, but that proven procedures can now be handled faster and more securely than before with system support.

“The switch to paperless picking has put an end to the paperwork and the warehouse management system ensures stock reliability, so that loading processes can also be made much more targeted and efficient.”

Marco Emken, Geschäftsführer Zentrallager Nowebau GmbH & Co. KG