Warehouse management software (WMS)

Warehouse management software in use

Indispensable nowadays:Anyone who has ever worked in a warehouse knows that warehouse processes have become increasingly extensive and complex over time. Where it used to be sufficient to pick using a paper picking slip, the use of warehouse management software is now essential. This is because it maps all goods movements in the company and enables warehouse staff to quickly and effectively monitor and react to all processes in the warehouse.

To do this, the warehouse management software generates tasks from the system and distributes them to warehouse employees via an MDE device, an industrial PC or via pick-by-voice. These systematic processes make your warehouse management transparent and efficient.

The warehouse management software

pLG WMS from proLogistik

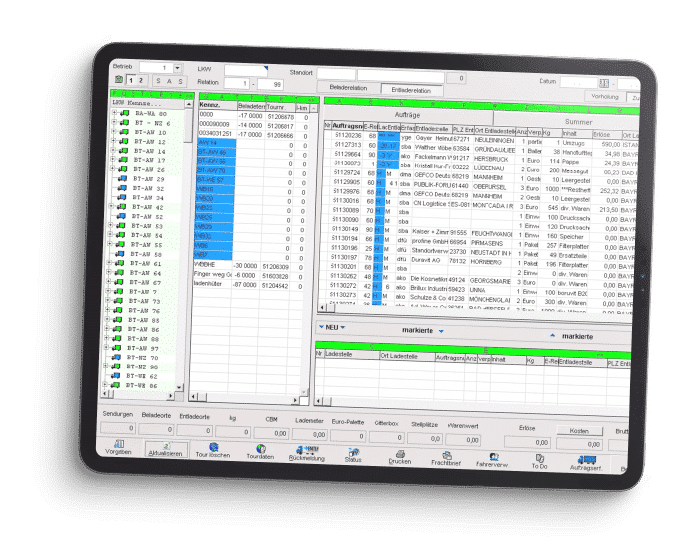

Flexible and powerfulWould you like to keep track of all your orders and stock movements? With the warehouse management software pLG WMS from proLogistik, you always have your goods at the right time and in the right quantity exactly where they are needed. With our help, you can speed up your warehouse processes and ensure faster picking and delivery of your goods.

With the warehouse management system pLG WMS you can:

- Online inventory management

- Less administrative work

- Complete documentation

- Automated processes

- Quality assurance

- Documentation obligation

- Short distances

- Faster throughput times

- Optimized processes

- Forward-looking warehouse planning

- Fewer shortages

- Better warehouse utilization

This distinguishes our warehouse management software:

Good warehouse management software offers you a comprehensive software solution for paperless, error-free and efficient handling of your intralogistics. To do this, the software seamlessly networks all stock, people and goods movements in your warehouse. With the online booking warehouse management system, you can transform your complex logistics processes from goods receipt to forklift control and picking through to goods issue into efficient processes.

A good warehouse management system makes the work of warehouse staff and logistics employees much easier, as everyone involved knows at all times which items are in which storage location at which time. A good warehouse management program offers a number of advantages: The WMS knows the storage capacities, warns the warehouse staff if the stock is too high or too low and finds the best possible storage location for the items.

Warehouse management software based on the modular principle

We at the proLogistik Group offer warehouse management software for intralogistics based on the modular principle. We recognize your needs, whether you need comprehensive individual warehouse management or a standardized industry package. With our warehouse management software pLG WMS, we provide a modular package for your individual needs, allowing you to select the right modules for your specific application.

For some industries, we offer special standard solutions that have been developed over decades of collaboration with customers. pLG WMS is available for the food industry and specific industry solutions are available for the building materials, sanitary and technical wholesale sectors. We also offer software modules for expanding an existing warehouse management system.

The advantages of our warehouse management software:

- Cost reduction through fewer stock-outs

- Time savings thanks to optimized warehouse processes

- Increased inventory security with better planning options

- Reduced excess stock of individual items

- Increased efficiency through forward-looking warehouse planning

- Increased productivity through paperless picking

- More transparency about warehouse operations

- Quality assurance through complete documentation

- Optimum personnel planning through better warehouse utilization

Warehouse management software for your company

A warehouse management system is recommended for any company that has a warehouse and wants to monitor and optimize its logistics processes. With a warehouse management program, small, medium-sized and large companies can always keep an eye on their stock levels. In addition, real-time stock levels can be called up at any time and sources of error minimized. Medium and large warehouses in particular are often dependent on warehouse management software due to their complexity or connection to an online store. Our references range from many medium-sized companies to corporate trading companies in a wide variety of sectors. Are you also looking for a digital solution for your warehouse management? Our team will be happy to help you.

All the functions of the pLG Store warehouse management software at a glance:

- Multiple transportations

- Dynamic block space handling

- Dock & yard management

- Order picking for catering and retail tours

- Empties processing and tour provision

- Batch management

- BBD management

- Vintage management

- Inventory management

- Autonomous warehouse management without overlaid WWS

- Manual order entry and order handling

- Client management | Warehouse money calculation and packaging

- Optional simple connection to WWS, ERP and control systems

- Time and route optimization

- Efficient route management and personnel optimization

- Forklift control and transportation optimization

- Serial number management

- Finished goods processing

- Retrograde booking mechanisms

- Time and demand-oriented material flow control to production

- Online inventory management

- Pick-by-voice picking

- Dispatch processing

- Returns management

- Chaotic storage bin management

- Temperature detection according to HACCP

- Weight control and SSCC intake

- Outgoing goods area management

- Resource planning

- Multi-order picking

- Pick & Pack – Online store integration

- Online inventory management

- Order and item-related volume calculation

We will be happy to advise you on our products

We are here for you.Give us a call or send us a message. We look forward to welcoming you.

proLogistik Holding GmbH

Fallgatter 1

44369 Dortmund

Tel.: +49 (0) 231 5194-0

Tel.: +41 (0) 44 200 40-00

Tél.: +33 (0) 251 81 85 85

Do you have questions about the ideal warehouse management software? We have just the right answers for you!