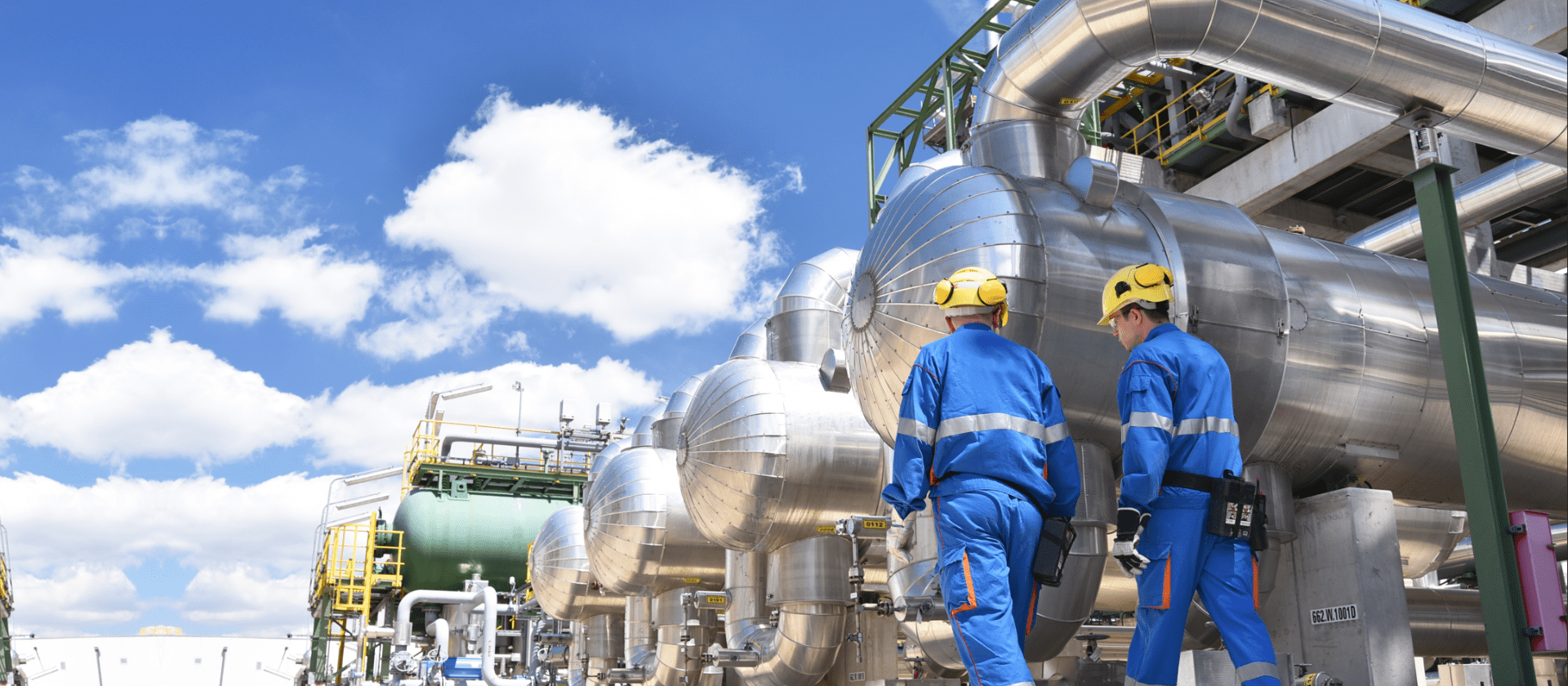

Plant construction

Warehouse management for plant construction

Logistics solutionsLogistics experts in the mechanical and plant engineering sector are often confronted with considerable challenges. On the one hand, the range of available tools and components is constantly expanding. On the other hand, market conditions are subject to constant change, which further increases the pressure to adapt and become more flexible.

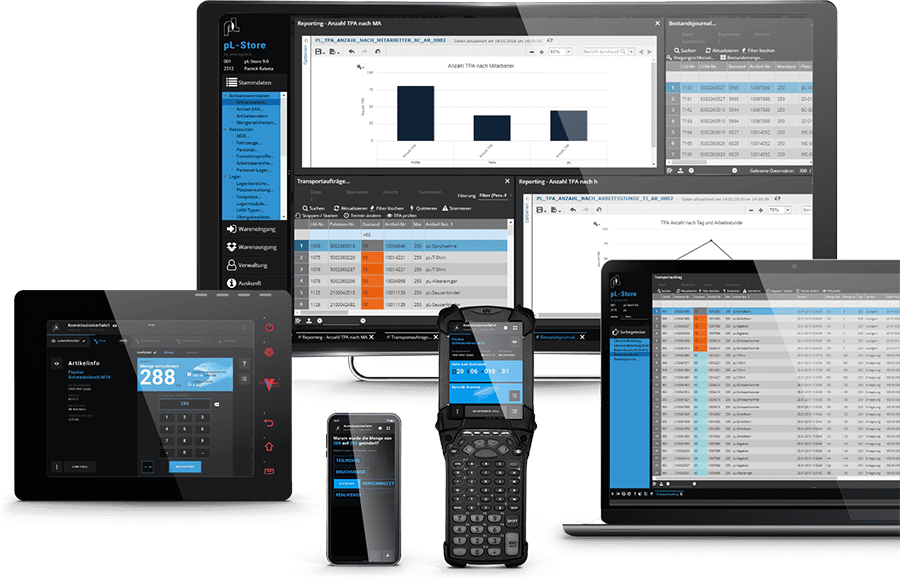

pLG WMS Industry

EFFICIENT & RELIABLEIn order to provide flexible intralogistics in the field of plant engineering, adaptable and seamless logistics are of crucial importance. This is exactly what our warehouse management software pLG WMS Industry stands for. It handles the efficient storage and supply of products and provides logistics experts with precise information on stock levels at all times thanks to continuous stock tracking. To ensure that production is continuously supplied with the required materials, items that fall below a predefined minimum stock level are automatically reordered.

Product highlights for mechanical production:

- Serial number management

- Finished goods processing

- Retrograde booking mechanisms

- Batch & serial number tracking

- Quality inspection & assurance

- Reduction of downtimes

- Time & demand-oriented material flow control to production

Our references

Tailor-made industry solutions

WHAT OUR CUSTOMERS SAYHardware of the proLogistik Group

Quality made in GermanyOptimize your employees’ working environment with first-class hardware from the pL Group. Our industrial PCs and back-of-hand scanners not only make work less problematic, but also withstand the toughest conditions. With production and service “made in Germany”, we guarantee quality at the highest level. You can also benefit from our first-class service team, which is always on hand to assist you after delivery.

The Transport Management System of the pL Group

Efficient, cost-saving & environmentally friendlyDiscover the PLG TMS – the ultimate solution for all challenges in the transportation industry. Whether heavy goods, hazardous goods or foodstuffs, our system optimizes tours and routes, cuts costs and reduces CO2 emissions. Maintain an overview and increase your customers’ satisfaction at the same time. With pLG TMS you are ideally equipped for any transportation task.

Manufacturing – production takes place here in logistics.

Benefit from the advantages

Tailor-made modulesIf tools and components of different sizes and weights are stored in highly compacted form, the required storage space can be reduced by up to 85%.

Sensitive components require special storage conditions – whether directly in clean rooms or in temperature and humidity-controlled storage. And that is what our WMS ensures.

Compact buffering enables materials to be stored temporarily between different production steps.

Do benefit from pLG products too

Our experts are at your disposal for an initial non-binding consultation. Make an appointment and get to know our industry innovations. Our logistics consultants will get back to you promptly.

Tested and approved

Our Warehouse Management SystemWe have our pLG Warehouse Management System comprehensively tested and subsequently validated annually by the Fraunhofer Institute for Material Flow and Logistics (IML) as a constant quality control measure. As a result, we are certified annually as a provider in the IML’s Online Warehouse Logistics Portal.

We offer you a holistic and personalized service

How else can we support you?With our logistics consulting, we support you in all logistical challenges, from the right strategy to optimal implementation.

Whether for your software, your hardware or your System Center. Whether you have questions, problems or defects – we support you with our support.

We will be happy to advise you on our products

We are here for you.Give us a call or send us a message. We look forward to welcoming you.

proLogistik Holding GmbH

Fallgatter 1

44369 Dortmund

Tel.: +49 (0) 231 5194-0

Tel.: +41 (0) 44 200 40-00

Tél.: +33 (0) 251 81 85 85