Dortmund/Nantes, 4th june 2025 – With the extension of the partnership between Orange and Kuehne+Nagel for the period 2026 to 2029, the proLogistik Group, as the provider of the Logistar warehouse management software, reinforces its contribution to their shared success. The company reaffirms its commitment to innovative logistics solutions and close collaboration with its long-standing customer Kuehne+Nagel. A key focus lies in the control functions of Logistar, which go far beyond traditional warehouse management and efficiently support the entire supply chain.

Long-standing Partnership

The implementation of Logistar, the warehouse management system (WMS) from the proLogistik Group (formerly DSIA), began back in 2002 to manage logistics operations related to e-commerce and the supply of Orange’s retail locations. Since then, the software solution, together with the locally based support team in France, has supported daily operations.

From Goods Receipt to Delivery – Logistar Supports Every Step

The solution covers all strategic logistics processes: managing incoming goods from multiple suppliers, dynamic slotting, control of internal material flows, order picking using various methods, and coordination of both B2B and B2C shipping processes. Real-time tracking and intelligent task management ensure optimal performance of the logistics site.

“The WMS Logistar is a robust and scalable solution that has adapted to Orange’s specific requirements for over 20 years. It helps us achieve our goals in terms of traceability, optimizing production capacity, and providing flexibility in packaging and content. Moreover, the technical teams at proLogistik are a real asset for Orange. Their expertise and willingness to respond to our needs allow us to jointly define solutions that meet our business, IT, and technical challenges,” explains Lionel Benezech, Director Supply Chain France, Orange/OF/Operations/SCF.

A Central Solution for Operations and Control

The WMS is connected in real time via API and standardized EDI interfaces with Orange’s information system, ensuring synchronization of order, inventory, and delivery data. It is also integrated with automated conveyor systems from CIUCH, which handle fast-moving goods. These systems enable automated packaging of e-commerce orders and semi-automated picking for stores and specialty retailers. Downstream, the WMS communicates directly with the transport management systems (TMS) of the freight carriers. It allows for automatic label generation, tour scheduling, manifest creation, and shipment tracking through to final delivery.

Logistar is designed to flexibly adapt to the business processes of its customers. It can be used at any workstation – whether stationary or mobile – and enables staff to manage goods receipt, storage, picking, packaging, and shipping in real time.

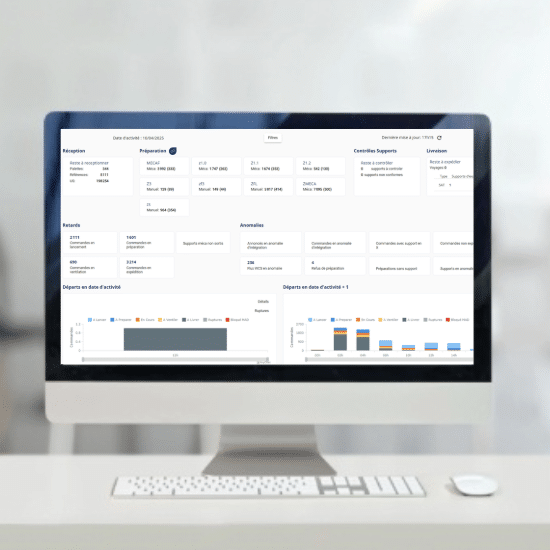

For managers, Logistar offers interactive dashboards, KPIs, and productivity and quality metrics, allowing precise operational control and quick responses to logistical disruptions. The user interface is fully tailored to specific role profiles, ensuring targeted functionality and user-friendly operation.

“The proLogistik Group delivers with Logistar a WMS that manages all logistics processes at the Kuehne+Nagel platform dedicated to Orange. This solution covers all key steps: goods receipt, inventory management, picking, and shipping. Logistar ensures full traceability of goods flows and is fully integrated both with Orange’s tools via EDI and with the WCS used to control conveyor systems on site,” says Jean-Michel Guillet, Logistics Manager at the Kuehne+Nagel site for Orange.

Intelligent WMS: When Data Predicts Performance

The WMS software stands out for its flexibility and has supported the continuous development of the warehouse since Kuehne+Nagel took over e-commerce logistics for Orange. It adapts to changing logistical processes and the diversification of goods flows while maintaining a high level of operational efficiency.

“The solutions are tailored to the increasing individualization of orders and the strain that e-commerce puts on logistics processes. Operational consulting is continuously carried out, based on analysis of the services provided, processes, and information systems. This enables the identification of value-added services and the development of appropriate software solutions,”

explains Patrick Claquin, Project Manager at the proLogistik Group.

The solution is designed for ongoing enhancement and will soon be expanded with artificial intelligence (AI) modules. These AI features will particularly enhance dynamic slotting: the goal is to predict the optimal product placement at goods receipt based on outbound forecasts, to reduce walking distances, shorten picking times, and maximize overall warehouse productivity.

Press contact

Stefanie Börtz

presse@prologistik.com | +49 231 5194 0

proLogistik GmbH | Germany | Fallgatter 1 | 44369 Dortmund

www.prologistik.com