How do you deal with the weather risk in retail? Weather plays a major role in retail and has a huge influence on consumer behavior, as the following example shows: Summer 2022: The heatwave has been over Europe for days. Everyone is sweating and only wants cool products like ice cream and beer. But you weren’t prepared for the heatwave and now have too few cool items in stock. What you can do to ensure this never happens again: Optimize warehouse processes with modern warehouse management software! And, of course, always keep an eye on the weather forecast. Minimize weather risk with intelligent warehouse management software Functional highlights of the pLG WMS – Warehouse Management Software: We could undoubtedly continue the list, because the warehouse management software has many other plus points. Were we able to convince you that you can keep an even better eye on the weather risk with intelligent warehouse management software?

News

AutoStore continues to gain ground. There are good reasons for this. However, the full potential of the system can only be exploited with precisely tailored integration software. Automated small parts warehouses (AKL) are proven classics in intralogistics. Depending on the requirements profile, operation takes place via storage and retrieval machines (SRMs), shuttles or robots, as with the AutoStore system. The latter move in an aisleless aluminum construction, stack the containers directly on top of each other and make them available just-in-time for order picking. The advantages are therefore practically obvious: in particular, a low space requirement in conjunction with a high storage density as well as flexibility and scalability speak for the robot-supported order fulfillment solution from the Norwegian manufacturer. But the achievable performance in terms of throughput and productivity is also a decisive argument for using AutoStore as an automated small parts warehouse (AS/RS). The option of automated, order-related pre-consolidation is also impressive – even at night if required. Organize and control automated warehouses efficiently However, the desired performance potential of AutoStore can only be exploited by using an intelligent warehouse management system (WMS), which integrates the system into the overall warehouse process and controls it on a daily … Read more

proLogistik Schweiz AG is the Swiss market leader in innovative and smart warehouse hardware, with over 40 years of experience in consulting, commissioning and sales of barcode scanners and other mobile terminals. We are familiar with all industries and know how to optimize your company’s warehouse processes with minimal effort. Buy barcode scanner How do we proceed? Before we start optimizing your intralogistics, we work with you to develop a project plan tailored to your needs. For example, we analyze your processes, incoming goods, outgoing goods, which tools are already in use and many other details. In the end, you have a robust, portable and cordless barcode scanner for your company and modernize your warehouse in the best possible way. Digitize your warehouse in no time at all with our barcode scanners Choose between barcode scanners from Zebra, ProGlove, FEIG or scan sleeves from Linea Pro. Every brand and every device has special features. That’s why professional advice and a testing phase are essential to ensure that you buy the right barcode scanner for your company and your employees. Buy barcode scanner – Target With a barcode scanner: You can also buy second-hand barcode scanners from proLogistik Sustainability is important … Read more

Smooth changeover: from paper picking to modern warehouse management software within a weekend – thanks to the use of the pLG WMS LOGIS MOVE’s standard functionality Until Thursday evening, Ritter Products AG and its sister company Rigaflex AG only used paper for order picking. The commissioning of the pLG WMS LOGIS MOVE warehouse management software was completed successfully and smoothly on Sunday after a complete inventory. Fast, efficient and reliable warehouse management software All processes were run through in the test system after comprehensive employee training and tested for live operation. The warehouse management software The pLG WMS LOGIS MOVE went into operation for day-to-day business on Monday. From kick-off to commissioning in just 4 months The modernization with the standardized warehouse management system pLG WMS LOGIS MOVE was successfully implemented within just 4 months. About Ritter Products AG and Rigaflex AG Ritter Products AG, based in Erlinsbach (Canton Solothurn), operates its own logistics platform with over 6,000 pallet spaces together with its sister company Rigaflex AG. Ritter Products offers a wide range of products from the Home Living & Utility, Garden & Do it areas as well as the corresponding services. The Rigaflex AG range consists of non-food products … Read more

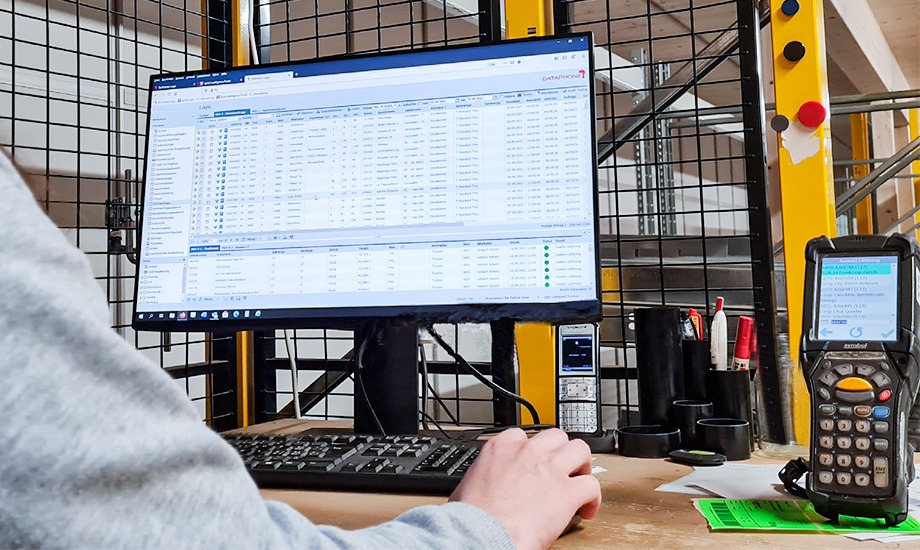

proLogistik Schweiz AG knows the secret to the success of smart warehouse management: With the innovative pLG warehouse management software, we can successfully implement sustainable and future-proof software in just 3 months, from commissioning to commissioning. The right warehouse management solution for every industry Thanks to decades of collaboration with companies in various industries, the warehouse management software has been further developed to create industry-specific solutions and additional WMS modules. Transform your warehouse management The latest release version of the pLG WMS offers you a flexible, fully release-capable and cloud-capable WMS version. With the pLG WMS you cover the current technical and functional requirements of your logistics, including a: With the pLG WMS, your logistics move faster and more efficiently Further information on the latest generation of sustainable and future-proof warehouse management software is available here: info@prologistik.com

With the latest release of its Warehouse Management System (WMS) pLG WMS LOGIS MOVE, Bio Partner Schweiz AG has opted for sustainable and future-proof software of the latest generation. proLogistik Schweiz AG’s pLG WMS LOGIS MOVE has been in use at Bio Partner Schweiz AG since 2013. After 7 years of close cooperation, the leading organic retailer has decided to continue the successful partnership and use the latest software architecture. Bio Partner is the leading service provider and wholesaler in the Swiss organic market. It is committed to a strong individual organic specialist trade. Under the motto “fresh, personal, partnership”, around 300 employees serve customers in the organic specialist trade, retail trade, gastronomy and the processing industry with a full range of organic products and services. Bio Partner operates sites in Seon (AG) and Saint-Blaise (NE) and has its own fleet of trucks. A modern, stable and reliable warehouse management system (WMS) such as pLG WMS LOGIS MOVE from proLogistik Schweiz AG is needed to ensure that all customer segments receive fresh and punctual deliveries of over 10,000 items ranging from fresh products such as fruit and vegetables, pasta and beverages to natural cosmetics and raw materials for the processing … Read more

The most important questions when evaluating warehouse management software: What is warehouse management software and what can it do? How can I optimize my warehouse with warehouse management software? Warehouse management software, or WMS (Warehouse Management System) for short, is the heart of every warehouse. Without a modern, functioning warehouse, you are no longer competitive today. The proLogistik Group has developed an innovative, standardized and flexible warehouse management software for the warehouse, in which the complete internal material flow is mapped. All goods movements such as goods receipt, storage, stock transfer, stock removal, dispatch and stocktaking are carried out in the warehouse management software. Why does every warehouse need modern warehouse management software today? Warehouse management software makes intralogistics processes more efficient and flexible. Employees work more efficiently and the company is well prepared for current and future challenges, enabling it to react quickly to changes. Why do companies need warehouse management software from the proLogistik Group? The WMS is a flexibly configurable and intuitive warehouse software that provides self-employed people, SMEs and large companies with the most efficient way of centrally controlling manual and automated warehouse processes. With our WMS, you increase profitability, increase storage capacity and reduce the … Read more

Barcode scanners – also known as barcode scanners – are the fastest way to track processes in the warehouse. How does a barcode scanner work? A barcode scanner is a data capture device that can read and transmit various barcodes. These barcodes are recognized purely optically with either red or infrared light. Each barcode reader consists of the actual reading unit and the downstream decoding unit. How can I reduce costs in the warehouse? You can reduce costs in your warehouse with a barcode scanner. How? With low investment costs and a high return on investment thanks to the excellent cost-benefit ratio between hardware and multifunctional barcode scanners. You can also use a barcode scanner to increase efficiency through the Internet of Things: automated data communication using barcode scanners, RFID and NFC tags and other sensors. A barcode scanner is easy to use The scanners are user-friendly and easy to use. This means that no training is required. Your employees can get started immediately after installing the devices. Which barcode scanner for my company? proLogistik offers various solutions for barcode scanning: Whether industrial, Bluetooth, long-range, ring scanners with 1D or 2D imager, laser or Linea Pro scanning sleeve – we … Read more

Without a modern warehouse management system, or WMS for short, you will no longer be competitive. proLogistik has developed an innovative, standardized and flexible warehouse management system for the warehouse, in which the complete internal material flow is mapped. All goods movements such as goods receipt, putaway, stock transfer, stock removal, dispatch and stocktaking are carried out in the pLG WMS. Who needs a warehouse management system? With the pLG warehouse management system, self-employed people, SMEs and large companies have the most efficient way of centrally controlling manual and automated warehouse processes. With the pLG WMS, you can increase profitability, increase warehouse capacity and reduce the error rate. How does a warehouse management system work? The pLG warehouse management system controls highly complex supply chain management processes: Yard management with automated goods receipt processing, monitoring, control, loading and dispatch control or the control of automatic components and robots with innovative merchandise management software. The system also enables both man-to-goods and goods-to-man picking. The WMS uniquely allows you to choose between fully automated and manual processes and, if desired, to combine them. What must a warehouse management system be able to do? proLogistik thus offers its customers the opportunity to digitize … Read more

The Transport Management System (TMS) is a system that deals with the planning, execution and optimization of physical goods movements. It is therefore a logistics platform with which users can control and optimize the daily operation of their transport fleets. Why do I need a transportation management system? Transportation management systems help companies move goods in (procurement) and goods out (shipping) with tools such as route planning and optimization, load building, operations management, freight auditing and payment, yard management, order visibility and carrier management. The primary goals of using a TMS are to improve transportation efficiency, reduce costs, improve real-time supply chain visibility and improve customer service. In addition, route planning for truck drivers has changed significantly in recent years: Transportation as well as the storage, provision and dispatch of goods are now increasingly carried out with the help of the Internet. Access to all orders at any time With the transport management system app, you can centrally plan, control, track and analyze all orders and routes based on data. Thanks to real-time data transmission, order adjustments can be made quickly and flexibly. The TMS software is used successfully in (wholesale) trade, industry, transportation and healthcare. Its a transport management … Read more