Sustainable logistics: resource-conserving use at all levels

Optimally coordinated logistics processes are the prerequisite for high-performance companies and organizational units. Sustainable logistics affects the exchange of goods and merchandise, but also of information. The problem with this is that logistics as such is not very ecological; around 20 percent of carbon dioxide (CO2) emissions in the EU are attributable to it, the trend continues to point upwards.

What characterizes sustainable logistics?

Which facets, forms and factors are relevant here in order to design logistics according to sustainability criteria in the future?

proLogistik approaches this topic from several perspectives and shows where adjustments can be made.

Focus on intralogistics: Sustainable logistics is multifactorial

The individual company that transports goods between individual countries or continents, for example, has only limited influence on the framework conditions. The situation is different on a smaller scale, i.e. internal logistics. First of all, however, it is important to understand that sustainable logistics is not a one-way street – environmental protection and cost savings go hand in hand here, and investments pay for themselves quickly.

In the following, we will give examples of selected aspects in order to better illustrate the facets of sustainable logistics:

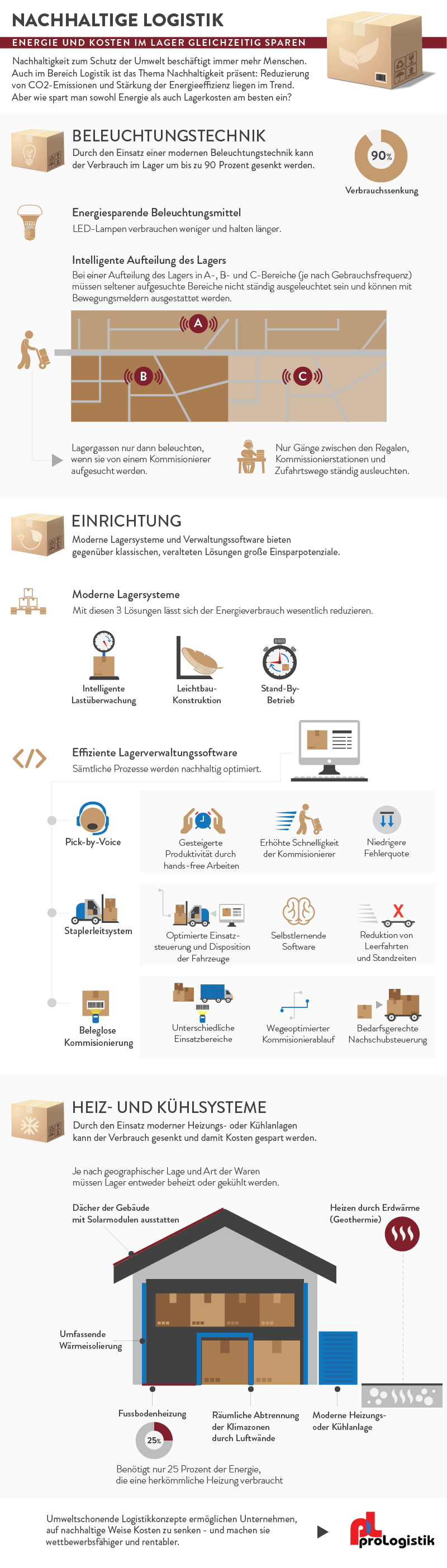

- Use of modern lighting technology minimizes consumption by up to 90 percent (especially LED = longer service life, lower consumption).

- Modern storage systems and picking methods increase the throughput frequency, reduce the error rate and therefore also have an economic impact.

- Storage areas can be logically divided according to the frequency of use of individual sub-areas and equipped with motion detectors to reduce energy consumption.

As you can see: Even small, intelligent adjustments can achieve a significant savings effect without any conversion work or extensions. Sustainable logistics is not only organizational, but also technical. More on this in the next paragraph.

Technical aids: warehouse management software as the basis for sustainable logistics

Detailed knowledge of goods and merchandise within the warehouse is essential in order to be able to carry out optimizations. However, this is often still characterized by old-fashioned, inefficient and error-prone picking methods. It is not uncommon for intralogistics to be constantly adapted in line with demand – but not planned and thought through from the ground up. However, a look at the benefits of modern warehouse management software illustrates the effect such measures can have on the sustainability of logistics:

- Digital inventory management creates planning security and reduces administrative effort.

- Paperless picking via pick-by-voice, for example, enables hands-free work, reduces the error rate and speeds up goods disposition.

- Stock levels displayed in real time enable better capacity utilization and planning and also reduce stock shortages.

- Interlocking processes and workflows ensure better throughput times and higher quality assurance at the same time.

Sustainable logistics based on high-performance warehouse management software (WMS) helps you to identify weak points, increase transparency and plan more flexibly overall. All goods movements are mapped via the system, making lengthy and cost-intensive processes a thing of the past. This reduces empty runs and downtimes, optimizes routes and intelligently controls the need for replenishment.

Changes to warehouse facilities: reduce energy consumption in just a few steps

The more fragmented individual aspects of a warehouse are, the more likely it is that practical problems will arise in the operational process. This starts with unspecific information, continues with a lack of transparency and extends to significantly increased costs as a result of low productivity. Sustainable logistics is conceived and realized holistically.

There are some measures that are relatively easy to implement and involve savings:

- Intelligent load monitoring

- Warehouse management based on stand-by operation

- Erection of storage areas in the lightweight construction

Sustainable logistics: save costs by using modern cooling and heating technology

Ecological measures as part of sustainable logistics not only pay for themselves relatively quickly, they are also often made more accessible through government subsidies or grants. A classic area for which companies can also apply for subsidies is the heating and cooling system. This allows energy-intensive warehouses, such as those in the food industry, to be managed much more cost-effectively.

Examples of sustainable logistics in this area:

- Expansion of factory and warehouse roofs with high-performance solar modules, the energy from which can be fed into the company or used financially in the form of state-guaranteed purchases.

- Integration of heating systems based on geothermal energy (geothermal heat), which are characterized by a high base load energy and an efficiency of almost 100 percent.

- Investments in building insulation (thermal insulation)

- Integration of underfloor heating, which requires significantly less energy than conventional heating systems

- Spatial division of the areas by so-called air walls (climate zone separation)

In short, sustainable logistics involves many individual factors that together have an immense effect. Optimized processes, lower costs and greater efficiency give companies a decisive competitive edge.