What are labels?

Labels for warehouse labeling: an overview of all common types

“Order is half the battle” – this is especially true in the context of modern and efficient warehouse management. After all, order pickers and other players must receive the necessary information in the shortest possible time. Labels are there to provide 100% traceable labeling, especially for “transshipment goods” where this information is initially missing. This refers to closed containers, various pallets, crates and the like.

By permanently scanning the labels, the products can be precisely located within the warehouse. Among other things, this helps to remove defective products quickly and easily. Complete labeling makes warehouse handling much easier, saves resources and speeds up processes.

The basics: each label consists of three components

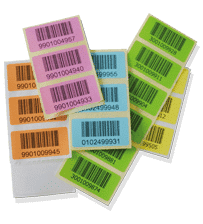

Labels are not just “any” stickers, but an element specifically designed for the application in the context of warehouse logistics. They are produced using a label printer and consist of the following components:

- Carrier material

- Adhesive (self-adhesive layer for better adhesion to the surface)

- Upper material (hand-printed or machine-printed)

Labels: more than just stock identification and labeling

In order to be able to specifically label storage areas, shelves etc., the right composition of these three components is required. The requirements in a deep-freeze warehouse, for example, are significantly higher than in “classic” reserve or spare parts warehouses, where barcode labels are often used.

The challenge: warehouse logistics forms the backbone of your company, because this is where you can see how efficiently processes are designed. On the one hand, however, the number of products and categories often exceeds a certain value, meaning that it is not possible to handle labels “at sight”. On the other hand, own and third-party goods are sometimes mixed, which makes precise control indispensable. Last but not least, there are countless types of goods, storage systems and the like to consider.

Labels must therefore fulfill various requirements and be suitable for the respective area of application. Materials such as paper, PE film, PVC or even thermal paper can be used here. More on this in the next paragraph.

An overview of the most important label shapes

To give you a better understanding of the many different ways in which labels are used in the warehouse, we would like to illustrate the typical forms. The most important properties and areas of use can also be found here.

Storage bin labels

Suitable for all standard rack types, e.g. shelving, live storage or pallet racking. Produced using either digital or thermal transfer printing. Materials such as polyester, Tyvek, textiles, PVC or frozen paper (down to -30° Celsius) are used. Such labels can be attached as magnets or adhesives (removable, permanent, extra strong adhesion).

PID labels

PID stands for pallet identification number, a nine-digit (consecutive) combination for unique assignment within a warehouse management system. Labels of this type are suitable for labeling parcels, pallets or other packages. They are available in various formats and can be attached using adhesive (removable, permanent, strongly adhesive) or a stapler.

Frozen food labels

Deep-freeze labels are often used so that items can be assigned even under constantly changing climatic conditions. Suitable for shelf life information, pallet, shelf or product labeling in deep-freeze storage and deep-freeze packaging. The special freezer paper withstands even extreme loads (down to -30° Celsius) as well as temperature fluctuations. Various types of adhesive are available, including those suitable for medical laboratories, the pharmaceutical sector and other segments.

Plastic signs

Suitable and frequently used for labeling block and storage locations in larger formats, as they are easy to read even from a distance. Thanks to the robust material (2 mm thick plastic), which is weather and UV-resistant, they can be used both indoors and outdoors. Black and retroreflective foil can be used for printing, which ensures scanning even in strong sunlight.

Reflective labels

Specially designed labels produced using thermal transfer printing that are suitable for warehouse and shelf labeling. Can be attached to smooth and slightly textured surfaces and extend the scanning range (up to approx. 21 meters). Especially suitable for block and high-bay warehouses.

Magnetic labels

The ideal choice for constantly changing labels, as magnetic labels can be removed without leaving any residue – without the need for screwing or gluing. Permanently adheres to steel shelves in cold stores or deep-freeze rooms. Suitable for all typical shelf types, including deep-freeze, flow, shelving and pallet racking. However, not intended for outdoor use due to the formation of flash rust.

E-paper labels

The modern version of labels in the warehouse, which enables digital labeling in different areas. Often used in supermarkets or retail in general. Easy to control by radio, the display is also flicker-free and can be read at any time, even in changing light conditions.