Warehouse management software for industry

pLG WMS Industry – for efficient warehouse processes in industry

pLG Warehouse Management System IndustryThe industry is demonstrably in a difficult situation. Corona and the war conflict have disrupted global supply chains and left stocks of raw and semi-finished goods short. Anyone who still wants to manufacture “just-in-time” or “just-in-sequence” will have to organize more and more time-consuming replenishment – if that works at all.

The continuing cost pressure and the variety of product variants desired by customers are not exactly helping to ease the situation either. This makes it all the more important to make optimum use of existing capacities by closely networking production and logistics.

In this situation, the benefits of digitization come into their own. This is because digitization offers every opportunity to use information more efficiently for agile and efficient process control in production-related warehouses. Particularly when it comes to optimizing supply security, a customized and functionally all-around secure Warehouse Management System (WMS) is the optimal door opener.

In addition, digitization can compensate for the shortage of skilled workers and enormously increase process reliability thanks to paperless order processing. Fewer errors occur, unscheduled waiting times, for example on assembly lines, are massively reduced and production quality increases.

The pLG WMS advantages at a glance

- Production supply

- Route optimization

- Traceability

- Performance

- Delivery quality

- Person dependency

What our pLG Warehouse Management System Industry does for you:

Quality arrives

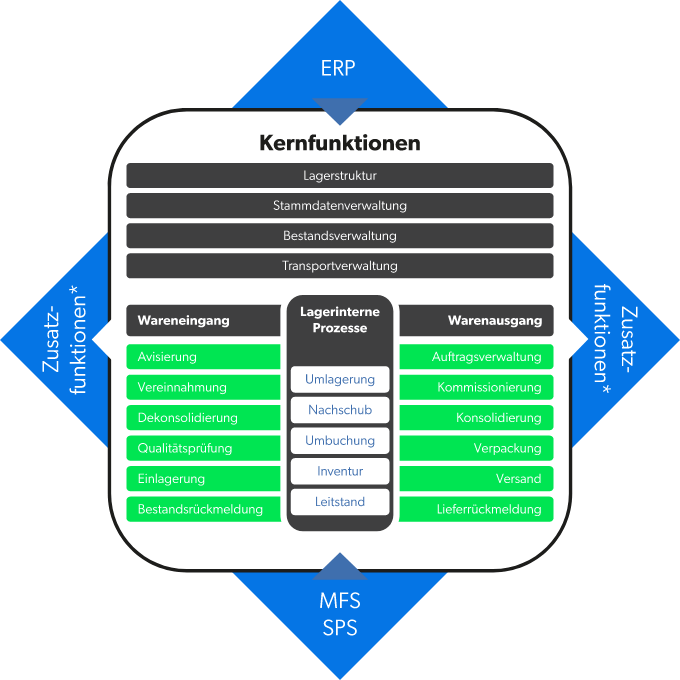

WHAT OUR CUSTOMERS SAYThe core and additional functions of our Warehouse Management System

A warehouse management system must be able to manage the entire intralogistics process error-free and paperless. This requires precisely coordinated processes, as this is the only way to control stock levels, process orders quickly and ensure reliable workflows.

Additional functions

- Batches

- Cross Docking

- Dock & yard management

- Double / multiple depth storage

- Dangerous goods

- Hazardous substances

- Weight control

- Handling Units-Measurement

- Kit formation

- Consignment

- Empties and loading aids

- (Multi-)client capability

- Multiple storage capability

- Best before date

- Package optimization

- Production supply / disposal

- Resource Planning / Labor Management

- Returns

- Serial numbers

- Slotting & Warehouse Reorganization

- Forklift guidance system

- Value Added Services

- Vendor Managed Inventory

- Scrapping

- Customs

Questions, requests or suggestions?

We are here for you.Give us a call or write us a message. We look forward to seeing you.