HONSEL Umformtechnik GmbH has built a new production facility, including a connected logistics section, at the company’s central headquarters in Fröndenberg an der Ruhr. Sector: Industry About HONSEL Umformtechnik GmbH Products made of wire – with the highest precision. This is a brief outline of the demands that HONSEL places on its own products. The portfolio ranges from simple cold-formed parts, such as rivets, nuts and bolts, to specially finished custom-made products and process-monitored systems for rivet automation. New building as an opportunity to restructure finished goods logistics In view of the constant growth in demand, HONSEL is constantly investing in capacity expansions at an operational level. A new production area with a direct conveyor connection has been created on 2,500 square meters of floor space. “We decided to introduce the goods-to-person process at intralogistics level in order to relieve our staff of long walking distances and search processes, while at the same time being able to operate more efficiently,” says Thomas Kleinert, Head of Operational Logistics. At the same time, the aim of the new system solution was to further increase the level of service for customers and overall quality. “As part of our digitalization strategy, it was also … Read more

Success Stories

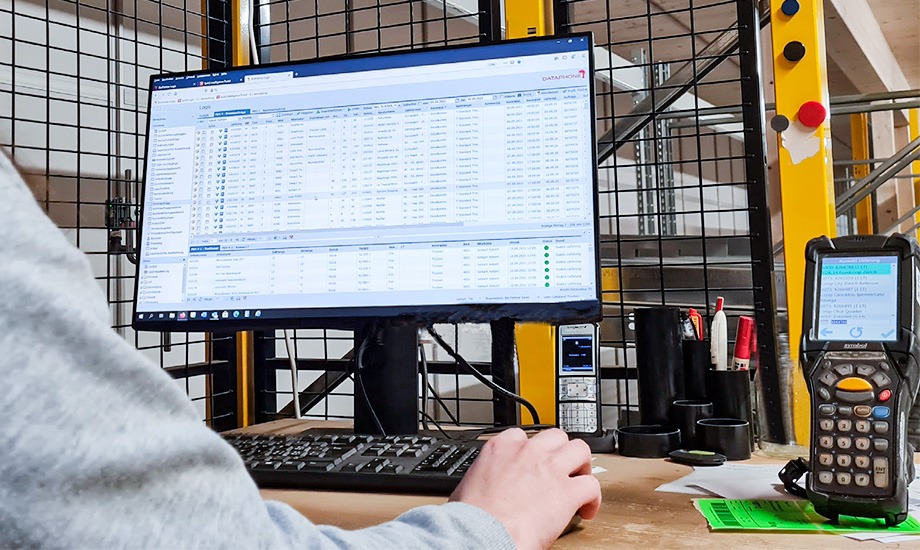

With the successive implementation of a new ERP system and industry-specific warehouse management software, Nowebau has put its business processes in Großefehn on a new, powerful and solid footing. Industry: Building materials wholesale About Zentrallager Nowebau GmbH & Co. KG Initial situation Until September 2017, intralogistics was controlled solely via the ERP software, which also includes a module for inventory management. “The disadvantage, however, was that printed route and pick lists were in circulation and special knowledge of the stocks and their storage locations was required,” reports Marco Emken, Managing Director of the Nowebau central warehouse. “This was exacerbated by the immense time pressure, which untrained employees in particular were barely able to cope with.” The question of whether the availability signaled by the ERP system was actually given in reality would also often have arisen in the context of customer support. (LVS) pL-Store® Techline with pre-programmed interface in ERP This software solution for warehouse and material flow control was specially designed for the building materials and sanitary industry as well as technical wholesalers and already covers their special requirements profile as standard.Since the go-live, all intralogistics processes have been controlled exclusively via pL-Store® Techline. The software communicates with the … Read more

Implementation of the warehouse management system pL-Store® Foodline including the use of proLogistik hardware. Industry: Food wholesale About Rullko Großeinkauf GmbH & Co KG Initial situation At the beginning of 2017, we decided to introduce a warehouse management system in order to increase stock accuracy, reduce errors in order picking and goods receipt and shorten order throughput times,” explains Uwe Langerbeins, Head of IT, Organization, Controlling, Logistics, Accounting and Administration at Rullko Großeinkauf GmbH & Co. At the same time, those responsible hoped to further improve traceability by optimizing best-before and expiration date and batch management (best-before date / expiry date = remaining shelf life). Advantages of the proLogistik Group software Since commissioning the pL-Store warehouse management system, the food wholesaler has benefited not only from paperless picking but also from a wide range of industry-specific functions within the warehouse management system. These include: Rullko also uses a reporting tool implemented by proLogistik. The aim here is to identify further potential for improvement through systematic monitoring in order to continuously improve performance in all storage zones. Fit for current and future requirements Rullko Großeinkauf in Hamm now manages a total of around 14,000 parking spaces, spread across two warehouse locations, … Read more

The pLG WMS LOGIS MOVE from proLogistik Schweiz AG has been in use at Bio Partner Schweiz AG since 2013. After 7 years of close cooperation, the leading organic retailer has decided to continue the successful partnership and use the latest software architecture. Sector: Food retail (LEH) About Bio Partner Schweiz AG The collaboration began in 2013 A modern, stable and reliable warehouse management system (WMS) such as pLG WMS LOGIS MOVE from proLogistik Schweiz AG is needed to ensure that all customer segments receive fresh and punctual deliveries of over 10,000 items ranging from fresh products such as fruit and vegetables, pasta and beverages to natural cosmetics and raw materials for the processing industry. With the latest release of its WMS LOGIS MOVE, Bio Partner Schweiz AG has opted for sustainable and future-proof software of the latest generation. The LOGIS MOVE WMS is provided in the cloud This means that no separate infrastructure is required and the resources are freely scalable. In addition, the customer gains server reliability thanks to the new deployment in a professional cloud. Availability is correspondingly higher. Customer-specific WMS facts Hardware Facts Components: “With the latest release of its warehouse management system (WMS) LOGIS MOVE, … Read more

With the new branch in the east of the Czech Republic, Albert Craiss GmbH & Co. KG is following the guiding principle of growing in the area of contract logistics beyond the German-speaking region in Eastern Europe. Industry: Freight forwarders & logistics service providers About Albert Craiss GmbH & Co KG Expansion in Eastern Europe Since May 2019, Craiss has been operating a warehouse with a direct link to production for an existing customer in Mohelnice, Czech Republic. The plant specializes in the production of geared motors, which are used in conveyor belts, among other things. The contract logistics provider is responsible for the receipt of goods, order-related picking, replenishment of assembly and packaging activities for shipping. Digitization is essential A special feature of the implemented software solution for warehouse management is the production station-related release of orders. This means that all required components must be picked sequentially. Forklift trucks, vertical order pickers and tugger trains are used for this. The replenishment request is triggered by scanning the assembly station and simultaneously recorded in pL-Store®. At the same time, a transport is activated for the order to be picked, which is waiting at a station designed as a buffer corridor. … Read more

Falk & Ross Group has successfully modernized the existing logistics center in Celrà, Spain. The main challenge in this complex project was to migrate to an up-to-date version of the pL-Store® warehouse management system with minimal impact on day-to-day operations. Industry sector: Wholesale promotional textiles About Falk & Ross Delivery quality at a glance Falk & Ross Group is one of the leading wholesalers of promotional textiles such as T-shirts, jackets, bags, caps, scarves and gloves as well as workwear and sportswear. The company has successfully modernized its pL-Store® warehouse management solution with the aim of making order processing more efficient across the board and taking new market requirements into account. In the long term, it has now been ensured that all customers in the domestic and neighboring markets are supplied quickly and reliably with goods of the desired quality. Software as a core element of a cross-location strategy “Comprehensively standardized software for warehouse management and material flow control prevents system disruptions, creates transparency and enables a reliable flow of information,” explains Tobias Brügmann, Head of Logistic Systems at the Falk & Ross Group. “The particular advantage of pL-Store® is that the software already includes a large number of relevant … Read more

The Ostendorf Group has successfully introduced the pL-Store® warehouse management system to further increase stock reliability and delivery quality. Industry: Building materials wholesale About Gebr. Ostendorf Kunststoffe GmbH Focus on transparency and inventory security Established structures and a paper-based working method imply that there were increasing deficits in terms of transparency, inventory security and delivery quality. This meant optimizing logistics processes, eliminating media disruptions and switching to full digitalization in order to ultimately implement robust processes within and between the plants. The main difficulty lay in finding a coherent concept for the efficient handling of inter-company logistics between the two northern locations. The challenge Fit for the challenges of today and tomorrow To reduce throughput times and increase adherence to delivery dates, the partners finally established a cross-docking process between the plants and across the three systems in use. Both plants act as both a supplier and a transshipment point. Another advantage is that stocks can be reduced and storage costs saved. At the same time, storage and retrieval processes are eliminated, which also reduces the time and money required. The system, designed as a channel storage system with 14,400 Euro pallet spaces, was put into productive operation in May … Read more

The wholesale company M. Bach GmbH, which specializes in building services, has replaced an existing warehouse management system at its central warehouse in Eschweiler with the industry solution pL-Store® Techline. Sector: Wholesale company for sanitary, heating and installation supplies About M. Bach GmbH Reasons for the change The reason for the warehouse management system change was the desire for increased performance and more flexibility in all functional areas. This was to be achieved on the basis of standardized software. The company also relied on the intralogistics system house proLogistik to select the necessary hardware for mobile data collection. Advantages of the proLogistik Group software The standard solution, specially developed for the building materials industry, has the advantages of an extremely wide range of articles as well as varying handling processes and variously designed storage locations. This saves time, as there is no need to program a large number of functions. Customer-specific WMS facts Hardware Facts Components: “At the same time, we are now well equipped to map growing and new product ranges in conjunction with changing process requirements directly in the warehouse management software in the future.” Udo Bach, CEO

Processes in the area of intralogistics are being aligned more efficiently and made even more flexible in order to be optimally equipped to respond to current and future challenges in a demanding market segment. Sector: Food retail (LEH) About K+K Klaas & Kock B.V. & Co. A good 7,000 employees at K+K ensure that customers can rely on the promise of quality and freshness. The range of standard products is constantly supplemented by trend and seasonal products. In addition, meat and sausage specialties under the “drilander” brand are produced in the in-house butcher’s shop. K+K has also made a name for itself as one of the largest reusable drinks suppliers in North Rhine-Westphalia. The selection currently comprises around 18,000 different items, which are delivered to the sales outlets via the fleet of around 120 vehicles. K+K is using the potential of digitalization to keep pace with its ongoing expansion and to make the company more flexible and efficient. Advantages of the proLogistik Group software All central applications for food retail are already stored in the WMS pL-Store® Foodline as standard. The following points are among the highlights: Highlights “The decision in favor of proLogistik was also supported by the fact … Read more

Volg Konsumwaren AG has been relying on proLogistik Schweiz AG’s warehouse management software since 2005. In order to continue to meet the constantly growing demands of the market in terms of intralogistics, Volg is relying on the release update – the latest warehouse management software version pLG WMS LOGIS MOVE. Sector: Food retail (LEH) About Volg Konsumwaren AG The collaboration began in 2005 In order to continue to meet the constantly growing demands of the market in terms of intralogistics, Volg opted for the release update in 2021 – the latest warehouse management software version pLG WMS LOGIS MOVE. Thanks to a flawless planning phase and a thorough testing phase, the release update was implemented without errors in just one night. Mega rollout in parallel in three distribution centers and six areas The pLG WMS LOGIS MOVE warehouse management system was put into operation simultaneously at the three Volg distribution centers in Winterthur, Landquart and Oberbipp. The changeover was successful. Customer-specific WMS facts Hardware Facts Components: “All sales outlets were supplied seamlessly without any errors or delays. The entire supply chain worked perfectly at all times without any noticeable impact. Stefan Näf, Head of Logistics/Informatics/Services, Volg Konsumwaren AG