What is warehouse management? Simply explained: With modern warehouse management, you can manage your goods in the warehouse. You also have an overview of the quantity, value and storage location of the goods at all times. This means that warehouse management is managed and organized efficiently. To ensure that warehouse processes are digitized smoothly and cost-effectively, sustainable and release-capable warehouse management software is required. The main task of warehouse management is to manage the goods during storage. With the right warehouse management software, you can manage your warehouse with little effort. Since proLogistik Schweiz AG has been a member of the proLogistik Group, we can offer you various warehouse management systems. Depending on the sector in which your company operates and your warehouse management needs, we can recommend the perfect intralogistics solution for you. Another advantage of the proLogistik Group is that we can also present you with the right hardware for your warehouse management. Warehouse management from a single source As a result, you have one contact person for your entire warehouse management. Remember, your warehouse management, like your employees, should be the be-all and end-all of your company! Do not hesitate and contact us today: info@prologistik.com We look … Read more

Products

At Hammer’s new logistics campus in Eschweiler, the multi-client-capable warehouse management system pL-Store® ensures fast, error-free and efficient omnichannel fulfillment. The 3PL provider has thus created the prerequisites for fully supporting its customers’ cross-channel supply concepts and also being able to flexibly meet new requirements. At the same time, the course was set to further strengthen the market position gained in a challenging environment. Hammer GmbH & Co KG, headquartered in Aachen, is one of the largest logistics service providers in the region. Together with the Hammer Group and other partners, the family business, which has been owner-managed for more than 70 years, operates a global service network in over 25 countries. Capacity increase to more than 105,000 square meters For many companies, outsourcing is still a sensible alternative to in-house logistics in terms of quality and cost-effectiveness. “We want to continue to grow and have invested in the construction of the Logistics Campus Eschweiler – LCE for short,” reports Tim Wilhelm Hammer, Head of Logistics. Focus on peak-compliant pick performance This is not the first time Hammer has relied on the high-performance Warehouse Management System (WMS) pL-Store® from proLogistik for warehouse management and material flow control. The collaboration with … Read more

For more than seven decades, K+K Klaas + Kock has been impressing customers with high-quality food and products from the region. But the topic of digitalization also drives the retail company. The latest milestone in the consistently pursued IT strategy is the implementation of a warehouse management system. With its help, processes in the area of intralogistics will be aligned more efficiently and made even more flexible in order to be well equipped to respond to current and future challenges in a demanding market segment. K+K Klaas + Kock B.V. & Co. began in 1950 with the confectionery business. With a keen sense for the potential expansion rates associated with the emerging wave of discount stores, the merchants established a large-space store in Nordhorn for the first time just six years later. Regional strength as a recipe for success A good 7,000 employees at K+K ensure that customers can rely on the promise of quality and freshness. The range of standard products is constantly supplemented with trendy and seasonal products. In addition, meat and sausage specialties under the “drilander” brand are produced in the in-house butcher’s shop. K+K has also made a name for itself as one of the largest … Read more

The wholesale company M. Bach GmbH, which specializes in building services, has replaced an existing warehouse management system (WMS) at its central warehouse in Eschweiler with the industry solution pL-Store® Techline. The reason for the change was the desire for increased performance and more flexibility in all functional areas. This was to be achieved on the basis of standardized software. The company also relied on proLogistik when selecting the necessary hardware for mobile data collection. No fully developed business plan, just a motorcycle and the desire to be self-employed – that’s all Matthias Bach needed when he laid the foundation stone for today’s M. Bach GmbH in 1945. The result was a wholesale company for sanitary, heating and installation supplies, which is now one of the most important in the sales region. With a range of more than 250,000 items, the choice is enormous and leaves nothing to be desired. These are located at the headquarters in Eschweiler as well as in Aachen, Mechernich and Pulheim. Agility pays off When asked about the reasons for the company’s continued success, Udo Bach, who today manages the wholesaler together with Michael Bach, remarks with a wink: “The market shows us that it’s … Read more

Together with the Dortmund-based intralogistics system provider proLogistik, the internationally active Falk & Ross Group has successfully modernized the existing logistics center in Celrà, Spain. The main challenge of this complex project was to migrate to an up-to-date version of the pL-Store® warehouse management system with minimal impact on day-to-day operations. This standard software puts the company in a position to supply its numerous customers in the domestic and neighboring markets with goods of the desired quality quickly and reliably, even in the long term. With more than 30,000 B2B customers and a product range comprising around 60,000 items, the Falk & Ross Group is one of the leading wholesalers of promotional textiles such as T-shirts, jackets, bags, caps, scarves and gloves as well as workwear and sportswear. In addition to an attractive product and pricing policy, the company, which was founded in 1981, impresses with a combination of international strength and an understanding of the requirements of local markets. The availability of goods and short delivery times are ensured by state-of-the-art logistics infrastructures in Germany, Spain, the UK and Poland. Falk & Ross primarily supplies customers from the B2B sector based in Spain, France and Italy via the logistics … Read more

At its new site in Mohelnice in the Czech Republic, Albert Craiss GmbH & Co. KG operates a warehouse with a direct link to the plant of a technology group. The central task of the contract logistics provider is to supply the workstations with components required for gearbox production in the exact sequence required. The warehouse management software pL-Store® from proLogistik ensures consistently synchronized processes. At the same time, high availability is ensured. Superfluous handling work is eliminated, as is constant parts tourism between the warehouse and production, as well as high inventories at the assembly stations. Contract logistics is a demanding business that thrives on professionalism, transparency and trust. Such a constellation is of substantial importance in the area of industry-related contract logistics. This is exactly what Albert Craiss GmbH & Co KG, headquartered in Mühlacker, Baden-Württemberg, is working on. The family-run logistics company, whose roots go back to 1931, employs almost 800 people and operates at 16 locations in six countries. Our expertise is correspondingly broad when it comes to implementing holistically developed, individualized logistics concepts. It is also important to constantly prove their effectiveness in operations. Expansion in Eastern Europe As a partner to manufacturing companies, the … Read more

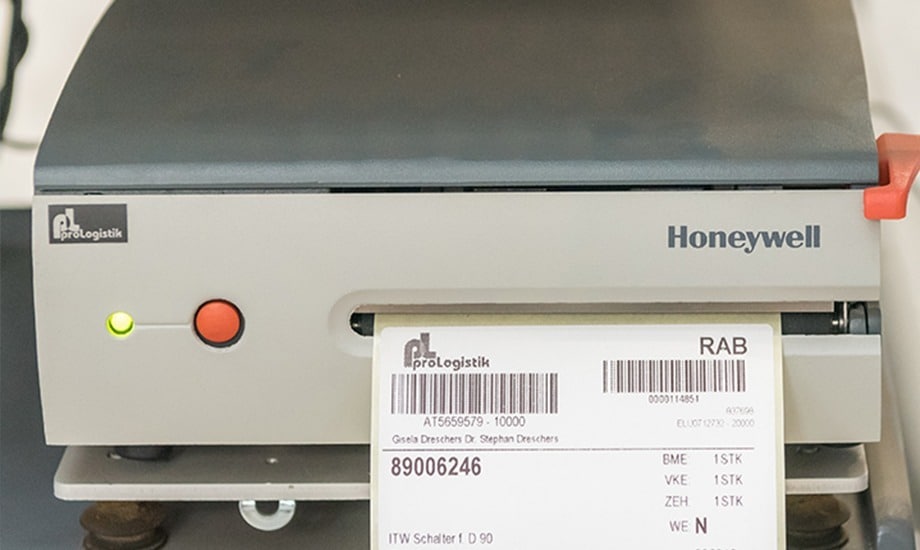

Label printers – But which is the best one for my industry? With a high-performance label and receipt printer, you can label your products quickly and easily. Labeling devices can be small, handy and mobile, making them perfect for use in offices, businesses and cold stores and can be used at temperatures as low as -30°C. But larger label printers, which are permanently mounted on a workstation, are also often used in production, logistics and retail and support employees in their day-to-day work. You can also obtain printers from us that allow you to print receipts on the move or track items using labels by printing out a barcode / QR code. We have all label printers Whether label printers with colored or black ribbon – together with our partners from the proLogistik Group, we can offer you a wide range of label printers! You also receive an all-round carefree package with these products! Interested? We look forward to hearing from you: info@prologistik.com

Due to the boom in e-commerce, Rofu wanted to be able to act faster, more efficiently and more flexibly in its intralogistics at its Hoppstädten-Weiersbach site. With over 90 stores, the company is one of the leading specialist toy retailers in Germany with a range of 20,000 products. Rofu installed the new Autostore small parts warehouse on a part of the site that had previously been used conventionally. “As we have already had very good experiences with ‘pL-Store’ from Prologistik at our Kornspeicher and Ramstein sites, particularly in terms of process reliability and flexibility, the WMS from the Dortmund intralogistics system house was also the right choice for our central warehouses.” Andreas Trampert, Head of IT at Rofu

Logistics service providers and 3PL providers are also upgrading and investing more in automation and digitalization. There are good reasons for this and modern warehouse management systems (WMS) are proving to be an indispensable artery for rapid and efficient order processing. Logistics service providers and 3PL providers are also upgrading and investing more in automation and digitalization. There are good reasons for this and modern warehouse management systems (WMS) are proving to be an indispensable artery for rapid and efficient order processing. The market demands service quality and speed However, with the growing demands on the quality of the services to be provided by 3PLs (Third Party Logistics) – in terms of speed and reliability – a rethink is taking place. This development is being driven by smaller orders due to the ongoing e-commerce boom. WMS – More than just warehouse management software Consistently implementing multi-channel concepts in both B2C and B2B business, precisely integrating value-added services, guaranteeing traceability, ensuring GDP compliance (GDP = Good Distribution Practice) and operating more sustainably – these challenges can only be met today with the support of a high-performance, standardized and scalable warehouse management system (WMS) that works in online mode or in real … Read more

Have you ever wondered where your employees should charge or store their barcode scanners? With the battery charging cabinet from proLogistik, you get a standardized cabinet with enough space for all barcode scanners. The picking equipment is easily and quickly accessible in the loading cabinet. proLogistik has been designing and certifying charging cabinets for barcode scanners for several years and has successfully added them to its product portfolio. All mobile data collection devices (MDCs) are stored in a central location, i.e. in the MDC charging cabinet, and are always ready for the next use with fully charged batteries. The loading cabinet is usually placed near checkrooms and/or punch clocks so that warehouse employees lose less time picking up and putting away work equipment. All MDEs such as barcode scanners from Zebra, Honeywell, proGlove etc. as well as smartphone scanners from Linea Pro and even mobile label printers are charged in the battery charging cabinet, which is only connected to the mains with a power cable connection. Highlights of the loading cabinet: Optional: Uninterruptible power supply in the event of a power failure You can customize your battery charging cabinet exactly as you want and/or need it: Enclosure colors, locking system, … Read more