From paperwork to digital intralogistics in just six months

Sideshore AG is a young, dynamic company in Wolfhausen (Canton of Zurich) that has been operating successfully in the sports wholesale business since 2006. As an exclusive Swiss importer and retailer, Sideshore sells trendy sports equipment and clothing from numerous manufacturers and brands.

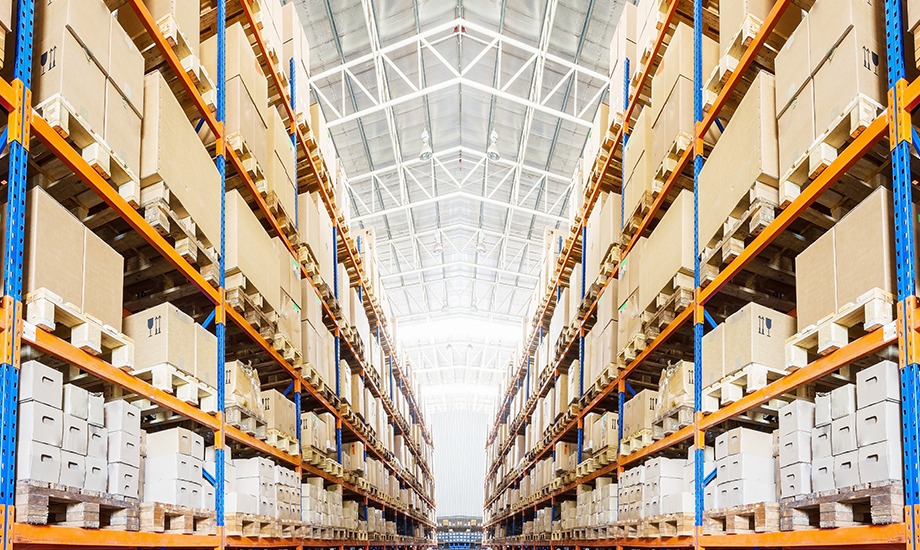

At the Wolfhausen site, around 14 employees store up to 10,000 different items and process an average of 40 to 50 customer orders per day.

A look back at the time without digital warehouse management

Since the company was founded, the company and the range of products have grown considerably. Before digitization with the LOGIS MOVE warehouse management software, the warehouse was spread over two parts of the building, each with two levels, where the ordered items were picked according to customer specifications. This meant that employees had to travel long distances and were only supported to a limited extent by the ERP system. This led to inefficiencies and errors within the logistics processes, as no warehouse management software or MDE devices were in use at the time.

Criteria that were important to Sideshore AG for the commissioning of digital intralogistics – including consideration of the strategic goals with regard to growth and space requirements:

- Increasing productivity and efficiency along the entire process chain by examining possible digitalization solutions in warehouse management and logistics process handling

- Reduction of errors by testing new technologies such as MDE devices

- Simplification of logistics and flow of goods

- Optimization of storage space through the use of automated container storage (Kardex) and mobile high-bay warehouses (Jungheinrich)

As a result, Sideshore AG reviewed its entire logistics processes and implemented a new, innovative logistics concept with Dataphone AG in 2021.

Solutions for digital intralogistics

Dataphone gained an initial picture of the current processes in order to present the new warehouse processes based on these impressions and with the support of the warehouse and project management:

1. electronic warehouse processes

All warehouse processes are now paperless. The data is processed electronically from goods receipt to goods issue and loading. All process steps are validated electronically (e.g. by scanning). This ensures end-to-end data consistency, reduces sources of error and all information on warehouse data and movements is available online and in real time.

2. online databases, worklist for maximum availability

LOGIS MOVE is linked to the Blue Office ERP system via the standard interface from the Business Connector. Thanks to the permanent exchange of data, recorded goods receipts are assigned directly to open orders and the stock is updated online. Duplicate data entry is no longer necessary and stock levels can be accessed transparently and in real time in logistics and administration. Purchasing, sales and administration have access to up-to-date inventory data at all times.

3. process management/process reliability

All process steps are specified by LOGIS MOVE. The activities carried out must be confirmed by scanning. This ensures complete process reliability and sources of error are reduced to an absolute minimum. The process management is kept simple so that new employees can work productively with the system within a very short time.

4. increasing efficiency and optimizing costs

In order to sustainably increase efficiency and significantly reduce costs, all process steps are specified in the LOGIS MOVE warehouse management software and thus also made measurable. The following objectives can be achieved with the available information:

- More efficient working methods reduce personnel costs/expenditure

- Training times for new employees are significantly reduced

- Complaints and returns due to incorrect deliveries are minimized

- Any errors that occur are traceable and can therefore be reduced

- The existing storage areas can be optimally utilized

- Transparent and timely information on stock levels allows a reduction in material stockpiling

5. avoidance of replenishment backlogs through proactive system decisions

The effort involved in replenishment processing is high. Picking stations could run empty before a replenishment has been carried out. Thanks to well-maintained logistics master data and up-to-date order data, replenishment orders are requested via the system. A good overview with prioritization prevents a concentration of replenishment orders and allows a smooth and resource-saving way of working.

6. efficient order picking thanks to hands-free process handling

The use of modern Zebra TC52 computers in combination with proGlove back-of-hand scanners enables hands-free and ergonomic working, as the glove-mounted scanner is worn on the back of the hand.

Commissioning of digital intralogistics after six months

After a short test phase, Sideshore AG was able to implement the warehouse management software LOGIS MOVE incl. Kardex connection successfully implemented.

Thanks to LOGIS MOVE from Dataphone AG, efficiency in the warehouse has been increased and the error rate in order picking reduced.

Conclusion from Sideshore AG

Since the introduction of LOGIS MOVE and the partial automation of our logistics processes, day-to-day work at Sideshore AG has changed fundamentally. With the exception of seasonal peaks, the majority of logistics work can now be carried out by just one logistician and our office team has correspondingly more capacity for customer-related activities such as advice and support. Errors in customer deliveries and inventory differences have also been noticeably reduced, if not minimized. The systematic monitoring of goods deliveries also gives us the opportunity to clarify delivery discrepancies with suppliers quickly and easily.

Despite an extremely short project duration and a tight schedule, we were able to switch operations to automated logistics in spring 2021, not least thanks to the active support of all parties, without any major interruptions in the support and service of our customers.

There are always situations in which our team remembers the time-consuming and manual processes and procedures before the introduction of LOGIS MOVE and we are all of the same opinion: “Things definitely weren’t better in the past!

Are you also interested in digital intralogistics?

The proLogistik Group is an expert in the development and implementation of sustainable supply chain systems. The warehouse management software developed in-house can be used to efficiently control, monitor and handle areas such as goods acceptance, goods receipt, storage, stock transfer, replenishment, goods issue, single customer orders, multiple customer orders, key date inventory, spontaneous inventory and many other processes in the warehouse.

Our supply chain experts will be happy to advise you!