With the latest release of its Warehouse Management System (WMS) LOGIS, Bio Partner Schweiz AG has opted for sustainable and future-proof software of the latest generation.

Dataphone AG’s WMS LOGIS has been in use at Bio Partner Schweiz AG since 2013. After 7 years of close cooperation, the leading organic retailer has decided to continue the successful partnership and use the latest software architecture.

Bio Partner is the leading service provider and wholesaler in the Swiss organic market. It is committed to a strong individual organic specialist trade. Under the motto “fresh, personal, partnership”, around 300 employees serve customers in the organic specialist trade, retail trade, gastronomy and the processing industry with a full range of organic products and services. Bio Partner operates sites in Seon (AG) and Saint-Blaise (NE) and has its own fleet of trucks.

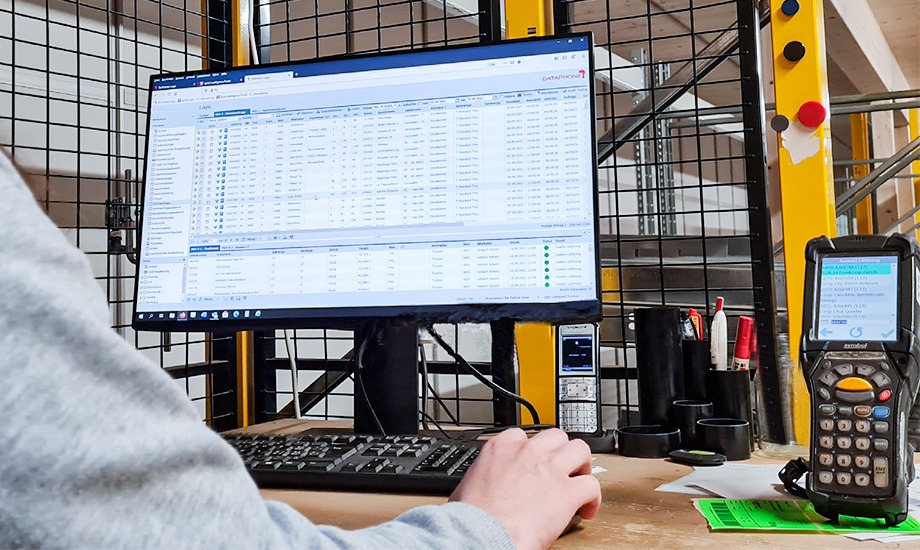

A modern, stable and reliable warehouse management system (WMS) such as LOGIS from Dataphone AG is needed to ensure that all customer segments receive fresh and punctual deliveries of over 10,000 items ranging from fresh products such as fruit and vegetables, pasta and beverages to natural cosmetics and raw materials for the processing industry.

Increased efficiency with the latest warehouse management system

The process workshops, at which the operational processes and configuration settings of LOGIS were reviewed and redefined, were followed by intensive system tests. Thanks to a detailed planning phase and close cooperation with the warehouse managers at Bio Partner Schweiz AG, the customer is ready for the release change in November 2020. The new architectural strategy that Bio Partner Schweiz AG is implementing as part of the release change is particularly exciting.

The LOGIS V21 warehouse management system is now available in the cloud.

This means that no separate infrastructure is required and the resources are freely scalable. In addition, the customer gains server reliability thanks to the new deployment in a professional cloud. Availability is correspondingly higher.

With WMS LOGIS Version V21, processes in the intralogistics sector are aligned even more efficiently and are significantly more flexible, enabling the company to respond to current and future industry requirements in the best possible way.

Why a WMS release change?

- Not only are business processes subject to constant change, the supporting IT systems must also always meet the latest technological, legal and functional requirements.

- A release upgrade reduces system maintenance costs and provides maintenance security for the software in productive use.

- Functional upgrades are included in the new release so that customers can easily adapt their system applications to the constantly growing requirements of the industry.

Functional highlights of the LOGIS V21 WMS software

- In addition to batch and best-before date management, the incoming goods process checks a wide range of inspection criteria, such as: Organic certificates, country of origin, delivery temperature, etc.

- Consolidation of several orders from the same suppliers: An excellent solution has been realized for several purchase orders from identical suppliers, so that a simultaneous receipt in the goods receipt is possible.

- LOGIS master data handling has a unique handling of conversion factors between pieces, liters and kilograms. Weight recording via electronically connected scales rounds off the range.

- Sophisticated putaway strategy: A more complex logic leads to better putaway suggestions. Goods are stored as close as possible to the respective picking location.

- System-generated warnings that inform employees as soon as the remaining shelf life of a product is exceeded, incl. the option of automated locking, which is enormously helpful.

- Picking end time calculation: This important key performance indicator calculates the expected picking end time, including the picking time, based on the current picking performance per warehouse area and the number of employees deployed. Inclusion of break times.

- ABC/XYZ classification of goods and warehouse: For chaotic storage bins, the WMS LOGIS calculates an article qualification based on the goods turnover. The category to which the goods belong must be configured for each storage bin. Storage proposals are then executed according to these strategies.

- The LOGIS WMS system also offers very detailed analytics and KPI options for warehouse managers, supply chain managers and logistics decision-makers. The control station enables maximum transparency and traceability of the flow of goods right down to item level.

- Outgoing goods: To avoid labor-intensive consolidation efforts, LOGIS offers pre-picking of small storage areas with system-guided merging of the main picking area. Transparent views in the control station enable good monitoring and control of the picking progress as well as loading and dispatch control.

- The LOGIS warehouse management system allows manual and conventional logistics processes to interact with fully automated systems in a unique way. At Bio Partner Schweiz AG, this applies to AutoStore. LOGIS has standard interfaces to well-known automated warehouse service providers for the control of automated components.

- Thanks to the suitability of the latest mobile hardware (mobile computers, forklift terminals, etc.), Bio Partner Schweiz AG has the opportunity to replace the outdated hardware operated with Windows CE.

We could undoubtedly continue the list, because the WMS LOGIS has many other plus points.

Dataphone has many years of experience in the organic trade, as we already support a number of market-leading organic retailers. We are therefore familiar with the national and international markets and their requirements. We know what concerns them and where the current challenges lie.